Stainless Steel Tube Expansion by SINOAK

Giriş

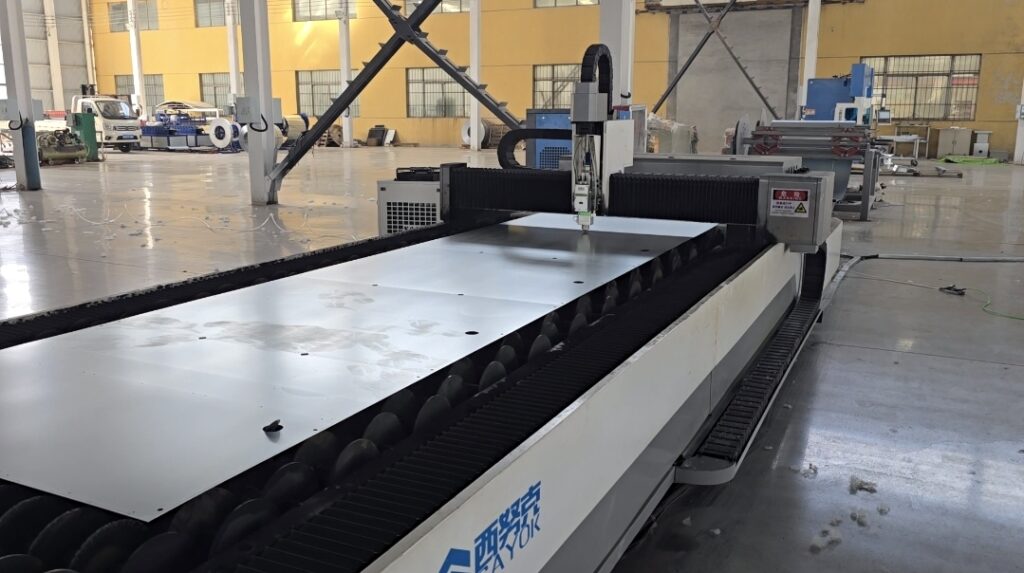

SINOAK'a Hoş Geldiniz Stainless Steel Tube Expansion page. Our advanced tube expansion solutions are designed to enhance the performance and durability of heat exchangers. With state-of-the-art technology and a team of skilled professionals, SINOAK ensures precision and efficiency in every tube expansion process.

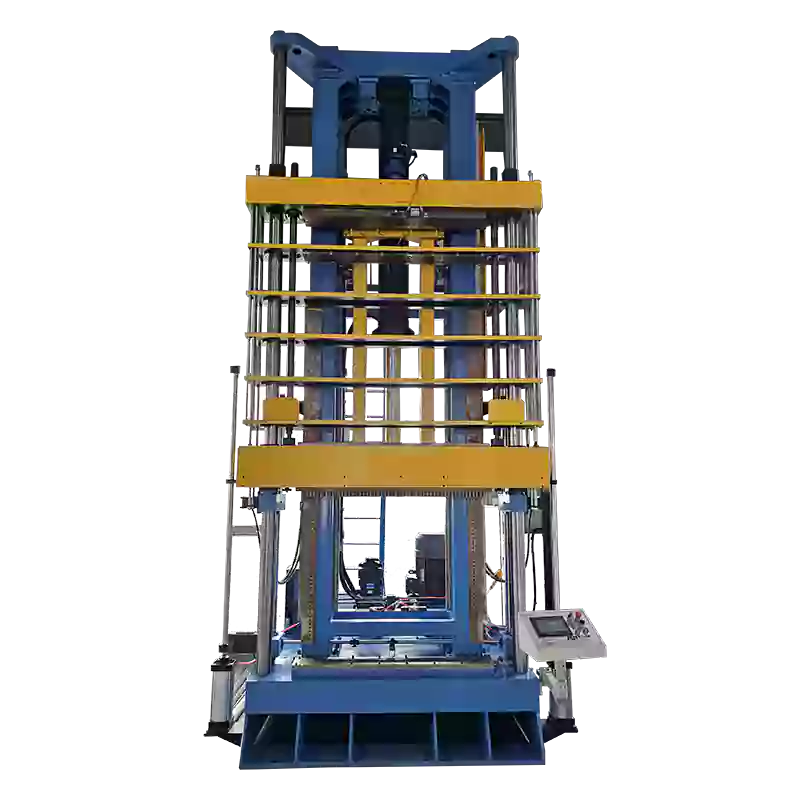

Key Features of SINOAK’s Stainless Steel Tube Expansion

Hassas Mühendislik:

Our tube expansion process guarantees accurate and consistent expansion, which is crucial for the efficiency and effectiveness of heat exchangers.

Yüksek Verimlilik:

Designed to optimize production processes, our tube expansion significantly reduces production time and labor costs, thus increasing overall productivity.

Dayanıklı Yapı:

Built with high-quality materials, SINOAK’s tube expanders ensure long-term reliability and performance, even in demanding industrial environments.

Özelleştirme Seçenekleri:

We offer the flexibility to tailor our tube expansion solutions to your specific requirements. Whether you need unique configurations or specific functionalities, our team can create a solution that perfectly aligns with your production needs.

Applications of SINOAK’s Stainless Steel Tube Expansion

SINOAK’s tube expansion is ideal for:

- Isı Eşanjörleri: Endüstriyel soğutma ve ısıtma sistemlerinde ısı transferinin iyileştirilmesi.

- Soğutma Üniteleri: Ticari ve endüstriyel soğutma sistemlerinde sıcaklık kontrolünün optimizasyonu.

- HVAC Sistemleri: İklimlendirme ve havalandırma sistemi performansının iyileştirilmesi.

- Otomotiv Radyatörleri: Verimli motor soğutmasına katkıda bulunur.

Teknik Özellikler

| Öğe | Şartname |

|---|---|

| Model | TE-100, TE-200, TE-300 |

| Tube Diameter | 6mm to 25mm |

| Malzeme Uyumluluğu | Stainless Steel, Aluminum, Copper |

| Expansion Speed | Up to 200 tubes per minute |

| Kontrol Sistemi | Dokunmatik ekran arayüzlü PLC |

| Güç Kaynağı | 220V/380V, 50/60Hz |

| Boyutlar | Müşteri gereksinimlerine göre özelleştirilebilir |

| Ağırlık | Modele göre değişir |

Why Choose SINOAK’s Stainless Steel Tube Expansion

Yenilikçi Teknoloji:

Our tube expansion process integrates the latest technology to ensure precise control and seamless process integration. This guarantees high-quality tube expansion.

Özelleştirme:

We provide tailored solutions to meet your specific production needs. Whether you need unique configurations or specific functionalities, our team can customize the tube expansion process to align perfectly with your requirements.

Güvenilirlik ve Dayanıklılık:

Ekipmanlarımız uzun süreli performans ve minimum arıza süresi sağlamak için uzun ömürlü olacak şekilde üretilmiştir. Bu sağlam yapı, zorlu endüstriyel ortamlarda verimliliği korumak için hayati önem taşır.

Müşteri Görüşleri

“SINOAK’s tube expansion solutions have significantly improved our production efficiency and product quality,” says Michael T.

"Bu makinelerin hassasiyeti ve dayanıklılığı eşsiz. Seçimimizden daha mutlu olamazdık" diyor Laura K.

Contact Us for Stainless Steel Tube Expansion Solutions

For more information on our stainless steel tube expansion, visit our İletişim Sayfası veya bize doğrudan şu adresten ulaşın [email protected].

WhatsApp ve WeChat üzerinden bizimle bağlantıda kalın: +86 15688803399

Daha fazlasını keşfedin

Diğer yüksek kaliteli ürünlerimiz hakkında bilgi edinin:

- Fin Press Machines: Advanced solutions for efficient heat exchanger fin production.

- Dikey Genişleticiler: Doğru boru genleşmesi için tasarlanmış hassas makineler.

- Fin Öldü: En yüksek kalitede fin üretimi için ürün yelpazemizi keşfedin.

Üretim teknolojisindeki en son gelişmelerden haberdar olmak için şu adresi ziyaret edin ASHRAE ve sektör haberlerini takip etmek için ACHR Haberleri.