Your Trusted Manufacturing Partner

Welcome to Shangdong SINOAK Co., Ltd., based in Dezhou, Shandong Province. We are a modern, specialized company dedicated to the production of precision dies, with a primary focus on the heat exchanger industry.

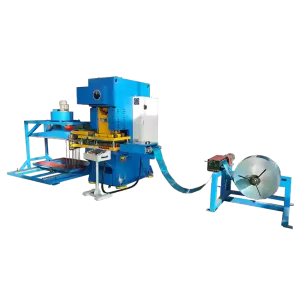

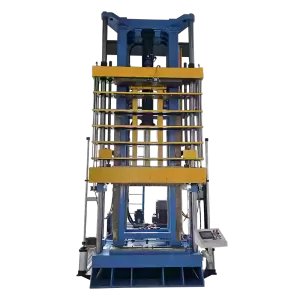

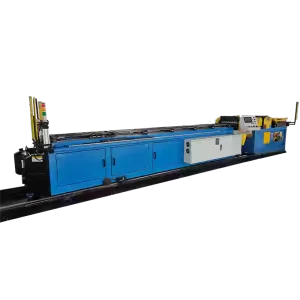

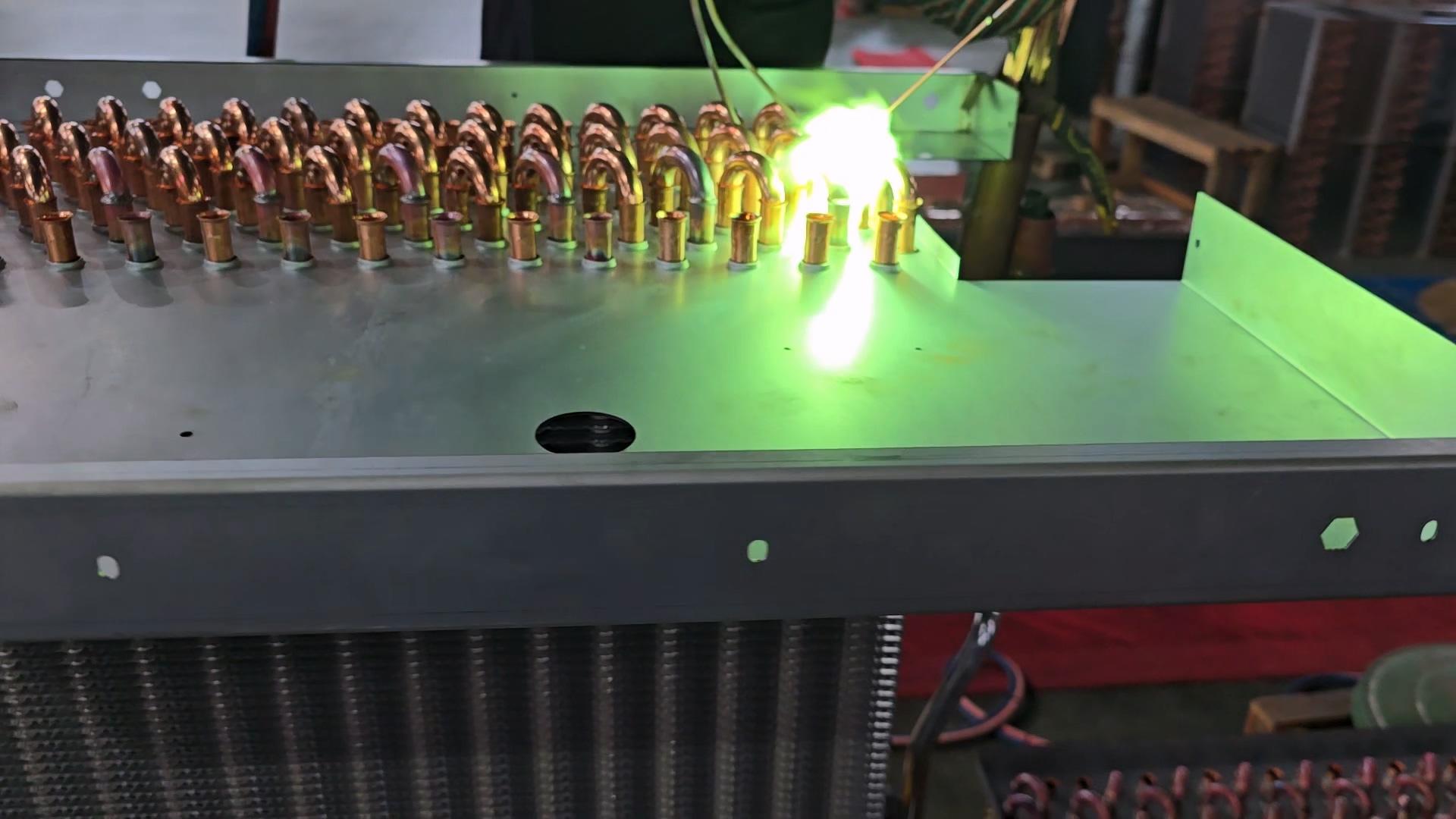

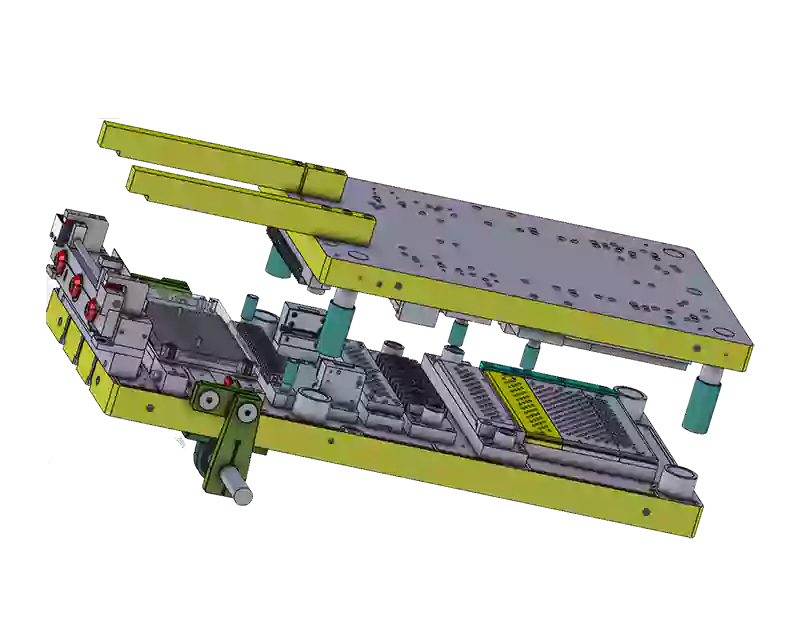

At SINOAK, we excel in manufacturing high-precision fin dies, including fin dies for air conditioning, refrigerators, automotive radiators, and cold storage applications. Our expertise extends to equipment that enhances production efficiency, such as vertical expansion machines and fully automated tube bending machines. We also offer automatic soldering machines to streamline your operations.

Our commitment to precision, innovation, and customer satisfaction sets us apart in the field. With our state-of-the-art equipment and dedication to high-quality craftsmanship, we empower businesses in the heat exchanger industry to achieve superior results, improve productivity, and stay competitive.

Join hands with Shandong SINOAK Co., Ltd. and experience the future of heat exchanger production equipment. Your success is our mission, and we’re here to elevate your manufacturing capabilities to new heights.

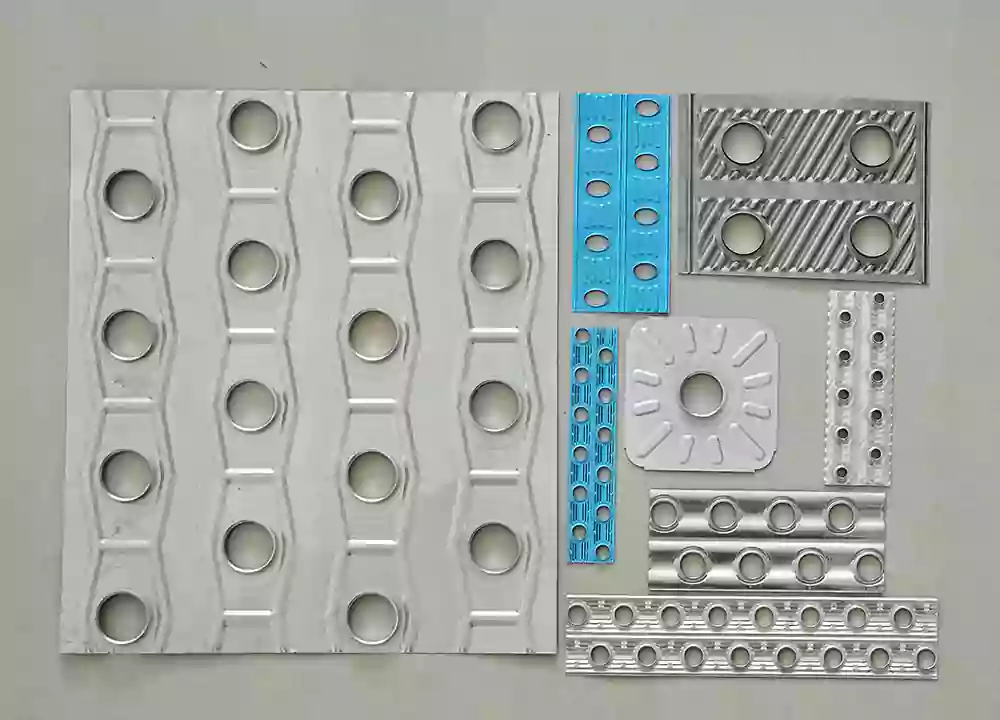

Product Showcase

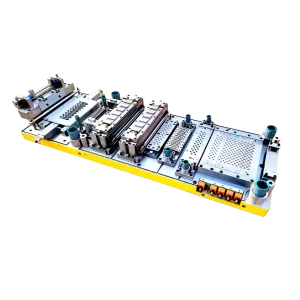

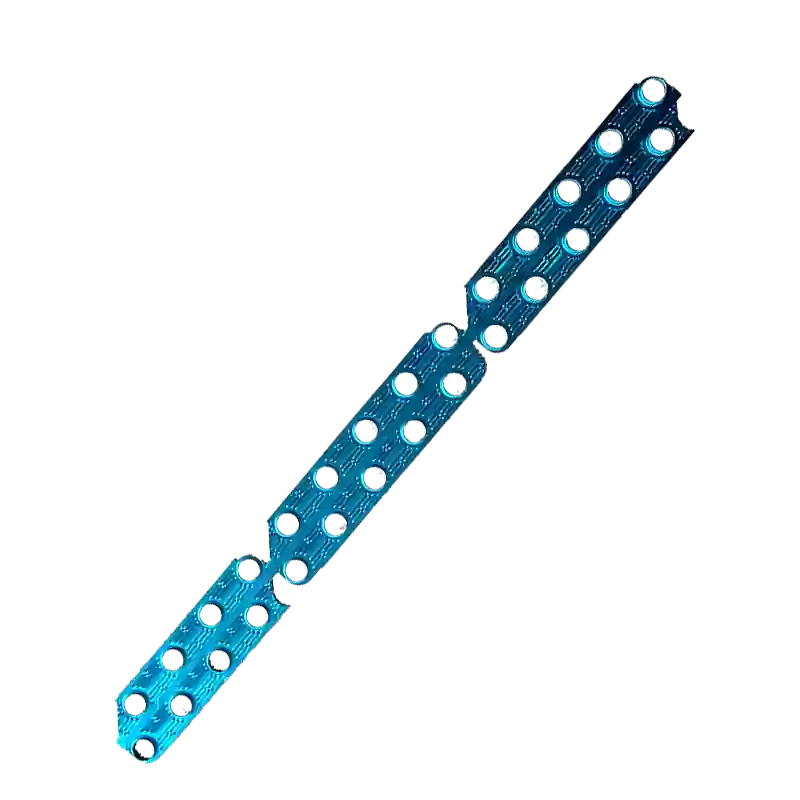

Air Conditioning Fin Die

Air Conditioning Fin Die is the heart of efficient cooling, meticulously crafting fins that enhance air conditioning performance. What sets our Home Air Conditioning Fin Die apart is its precision engineering, ensuring top-quality fins that elevate your systems’ efficiency to new heights.

Wave Fin Die

The Wave Fin Die, commonly employed in applications such as condensers, evaporators, and surface coolers, is designed to optimize heat exchange by incorporating a wave-like pattern into fin structures. This innovative design enhances thermal performance, making it a preferred choice for various cooling and refrigeration systems.

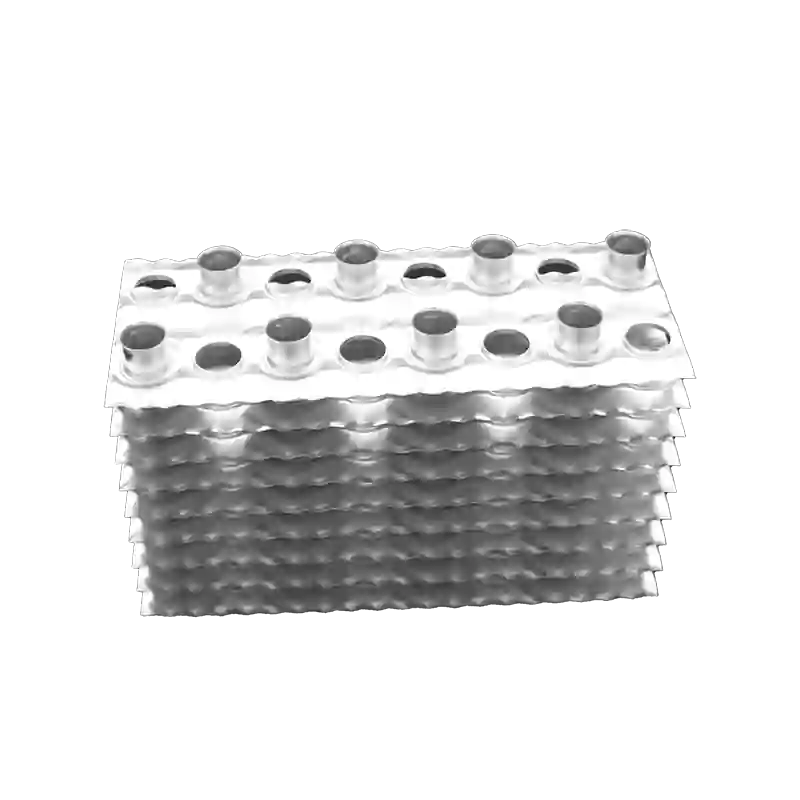

High Collar Edge Fin Die

The High Collar Edge Fin Die is a specialized tool primarily employed in the refrigeration and cold storage industry. Notably, it incorporates electric heating elements within the fin structure, serving the crucial function of defrosting. This feature ensures efficient and reliable defrosting in refrigeration systems, making it indispensable for cold storage applications.

Get Your Custom Fin Die

As SINOAK, a leading manufacturer of heat exchanger production equipment, we take pride in our ability to provide tailored solutions for our customers in three key areas:

Through our comprehensive OEM services, we empower you to specify not only the fin dimensions but also the materials and shapes that best suit your production needs. SINOAK is dedicated to delivering heat exchanger solutions precisely tailored to your requirements.

Fin Design Details

Here are five key design details when it comes to fin dies:

- Precise Fin Dimensions: SINOAK specializes in crafting fin dies with exact fin dimensions, ensuring optimal heat transfer and efficiency.

- Customized Material Selection: Our fin dies are tailored to your needs, with material choices optimized for thermal conductivity and corrosion resistance.

- Innovative Fin Shapes: We offer innovative fin shapes, including plain, serrated, or corrugated fins, designed to maximize surface area for enhanced heat exchange.

- Precision Tooling: Our fin die feature precision die cavities and punches, ensuring consistent and accurate fin production, vital for maintaining quality and repeatability.

- Efficient Cooling and Lubrication: SINOAK integrates efficient cooling and lubrication systems into fin die designs, prolonging fin die life and ensuring smooth operation.

These design details collectively contribute to the performance and longevity of fin dies, ultimately impacting the overall efficiency of heat exchangers in various applications.

Characteristics of fins

Types of Fins:

- Plain Fins: Common and increase surface area for heat transfer.

- Serrated Fins: Feature serrated surfaces for enhanced heat exchange.

- Louvered Fins: Improve airflow for efficient cooling.

- Blue Film Fins: Corrosion-resistant, ideal for harsh environments.

- Scale Fins: Scale-like patterns increase heat dissipation.

- Microchannel Fins: Tiny channels maximize surface area.

Functions:

- Enhanced Heat Transfer: Fins boost heat exchange efficiency.

- Efficiency Improvement: Tailored designs optimize performance.

- Corrosion Resistance: Some fins resist corrosion, extending lifespan.

- Customization: Choose fin type to match specific heat exchanger needs.

Fin Application

At SINOAK, we specialize in crafting custom heat exchanger production equipment, including fin dies, fin production lines, vertical expansion machines, and fully automated tube bending machines. Our versatile solutions cater to a wide range of applications, from refrigeration and air conditioning to automotive radiators, cold storage, agricultural greenhouses, solar thermal systems, and air-source heat pumps. We’re dedicated to providing precision equipment that enhances efficiency and performance across various industries.

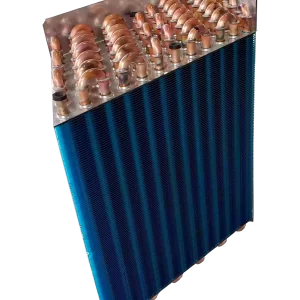

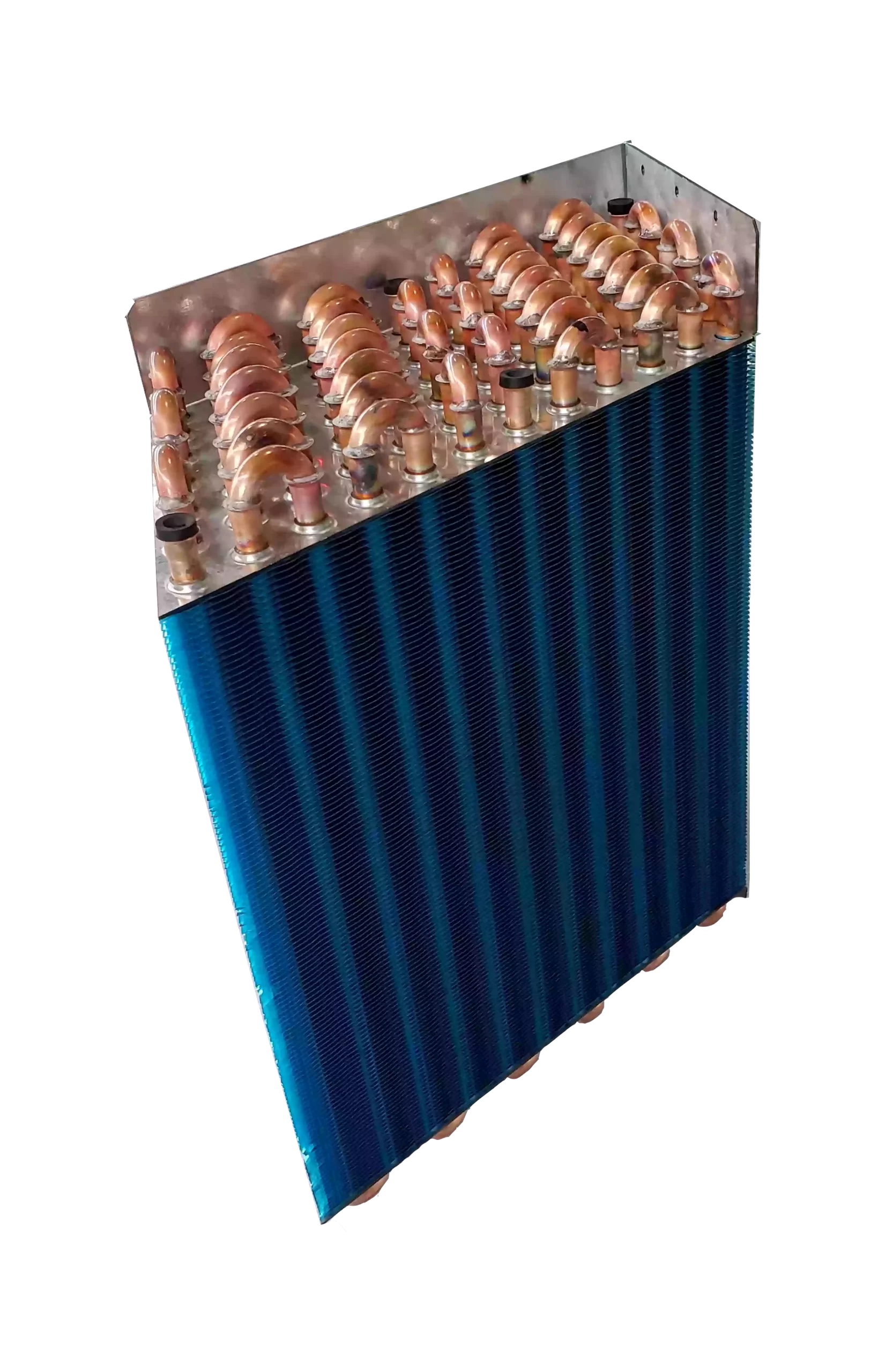

Condenser

Evaporator Condenser for Domestic Air Conditioners.

Refrigerator

Here’s a modified version for use in refrigerator evaporators.

Evaporators

For evaporators with high corrosion protection requirements

Small industrial air conditioner

SINOAK optimizes small industrial AC condensers

Why Choose Us as Heat Exchanger Equipment Supplier

Professional and Advanced Equipment

Advanced Manufacturing Processes: Our state-of-the-art processing techniques ensure precision and quality in every product we offer, from fin die molds to fin production lines, vertical expansion machines, and fully automated tube bending machines.

Low Price and High Quality

Extensive Production Experience: With years of industry expertise, SINOAK brings a wealth of knowledge to cater to various applications, including refrigeration, air conditioning, automotive radiators, cold storage, agricultural greenhouses, solar thermal systems, and air-source heat pumps.

Fast and Convenient Delivery

Cutting-Edge Technology: SINOAK stays at the forefront of technological advancements, allowing us to provide you with the latest innovations in heat exchanger equipment, enhancing performance and efficiency.

Best After-sales Service Provided

Comprehensive Factory Setup Solutions: Beyond equipment, we offer complete factory setup solutions, guiding you through the entire process, from design to implementation, to ensure seamless production in your chosen application.

Our Fin d Die Factory

What Our Other Customers Say About Us

After-Sales Support

SINOAK – Your Trusted Heat Exchanger Equipment Partner

Applications Across Industries: Our versatile product range serves various industries, including refrigeration, air conditioning, automotive radiator manufacturing, cold storage, agricultural greenhouses, solar thermal systems, and air-source heat pumps.

Comprehensive After-Sales Support: We pride ourselves on offering top-notch after-sales service, including:

- Technical Assistance: Our experienced team provides technical guidance and support to ensure optimal equipment performance.

- Maintenance and Repairs: We offer maintenance services and quick response for any necessary repairs, ensuring minimal downtime.

- Spare Parts Availability: We maintain a stock of essential spare parts, ensuring they are readily available when needed.

- Training Programs: We provide training programs to equip your team with the knowledge and skills to operate and maintain the equipment effectively.

- Remote Video Guidance: We offer remote video guidance for troubleshooting and operational assistance, ensuring real-time support.

- On-Site Service: Our experts can visit your site for hands-on support and personalized assistance.

With SINOAK, you not only receive top-quality heat exchanger equipment but also a commitment to ensuring your success through exceptional after-sales service and support, whether it’s remotely or on-site.