Mastering the Welding Process for Cold Storage Evaporators

Introduction to Cold Storage Evaporators

Cold storage evaporators play a critical role in the refrigeration systems used in cold storage facilities. These evaporators are responsible for absorbing heat from the stored goods and maintaining a consistent low temperature to preserve the quality of perishable items. Designed for efficiency and reliability, cold storage evaporators are a key component in ensuring the effectiveness of cold storage units.

The Importance of Welding in Cold Storage Evaporator Production

The production of cold storage evaporators involves several crucial processes, with welding being one of the most important. Proper welding ensures the integrity of the evaporator, allowing it to function efficiently without leaks or failures. Gas welding, specifically, is often used in the production of cold storage evaporators due to its precision and ability to create strong, durable joints.

The Gas Welding Process for Cold Storage Evaporators

Precision Welding for Enhanced Durability

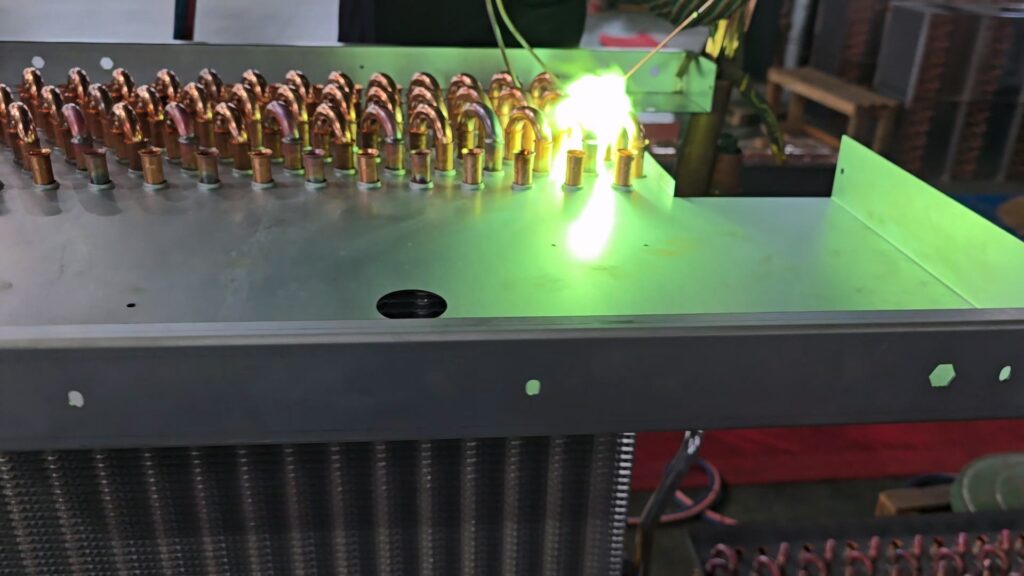

Gas welding is the preferred method for joining the components of cold storage evaporators. This process involves using a gas flame to melt the metal surfaces that need to be joined, creating a strong bond as the metal cools and solidifies. The use of gas welding in evaporator production ensures that the joints are leak-proof, which is crucial for maintaining the evaporator’s efficiency and longevity.

Steps in the Gas Welding Process

- Preparation: Before welding begins, the surfaces to be joined are cleaned and prepped to ensure a strong bond. This includes removing any impurities or oxides that could weaken the weld.

- Alignment: The components are then carefully aligned to ensure precision during the welding process. Proper alignment is critical to avoid any gaps or misalignments that could lead to leaks.

- Welding: A gas torch is used to heat the metal surfaces to their melting point. As the metal melts, a filler material is often added to the joint to strengthen the weld.

- Cooling: Once the welding is complete, the joint is allowed to cool gradually to prevent any cracks or weaknesses from forming. This slow cooling process ensures the durability of the weld.

- Inspection: After cooling, the weld is inspected for any defects. Non-destructive testing methods are often employed to ensure the welds meet the required standards.

Advantages of Gas Welding in Cold Storage Evaporator Manufacturing

- Strength and Durability: Gas welding produces strong, durable joints that can withstand the stresses of operating in low-temperature environments.

- Precision: The process allows for precise control over the weld, ensuring that the evaporator components are joined accurately.

- Versatility: Gas welding can be used on a variety of metals, making it ideal for the diverse materials used in evaporator construction.

Conclusion

In conclusion, the welding process, particularly gas welding, is a vital aspect of manufacturing cold storage evaporators. By ensuring strong and durable joints, gas welding enhances the efficiency and longevity of evaporators, which are essential for maintaining the integrity of cold storage systems. At SHANDONG SINOAK CO., LTD., we specialize in producing high-quality cold storage evaporators with meticulous attention to the welding process, ensuring our products meet the highest standards of performance and reliability.

Related Information

- Learn more about our advanced fin press lines for high-precision manufacturing.

- Explore our comprehensive solutions for fabricación de intercambiadores de calor.

External Industry Insights

- Stay updated with the latest trends in cold storage technology by visiting ASHRAE.

This content is optimized for SEO and includes both internal and external links to improve the webpage’s visibility and authority.

8qfhyc