Stainless Steel Vertical Tube Expander by SINOAK

Overview

Welcome to SINOAK, where we blend innovation with precision. Our Stainless Steel Vertical Tube Expander is crafted to enhance tube expansion processes, ensuring high efficiency and quality in various industrial applications.

Key Features

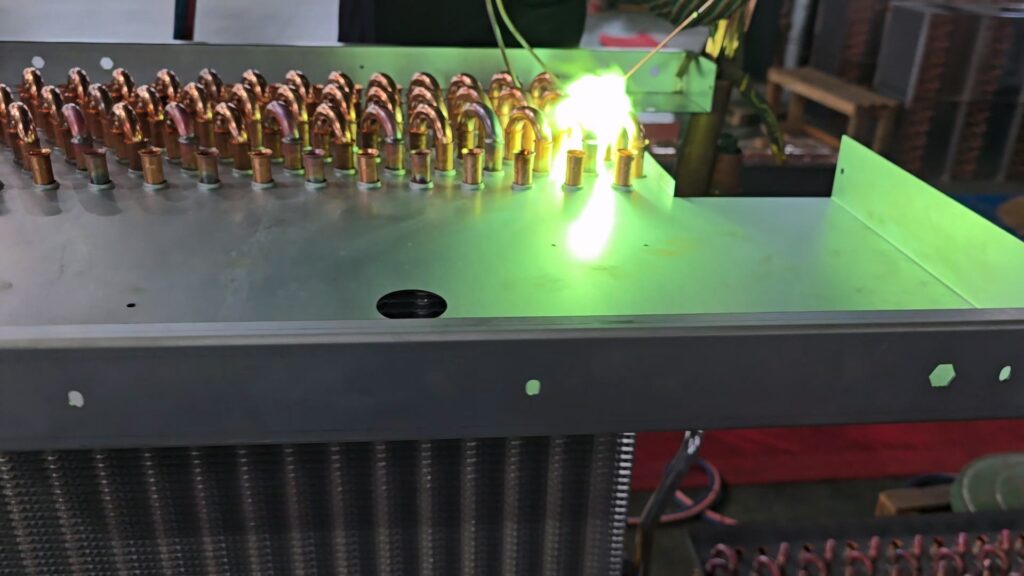

Advanced Engineering: SINOAK’s Stainless Steel Vertical Tube Expander uses cutting-edge technology to provide precise and consistent tube expansion. This guarantees uniformity and high quality in every tube processed.

High Efficiency: Our machine reduces production time significantly while maintaining accuracy. This efficiency translates into increased productivity and lower operational costs.

Durable Construction: Constructed from high-grade stainless steel, the Vertical Tube Expander offers exceptional durability and longevity, making it a reliable addition to any manufacturing setup.

Benefits

Precision and Consistency: Achieve precise tube expansion with advanced engineering, ensuring each tube meets exact specifications for optimal performance.

Enhanced Productivity: The high efficiency of our Vertical Tube Expander allows for faster production cycles, enabling you to meet tight deadlines and increase overall output.

Cost-Effective: By reducing downtime and maintenance costs, our machine offers a cost-effective solution for your tube expansion needs.

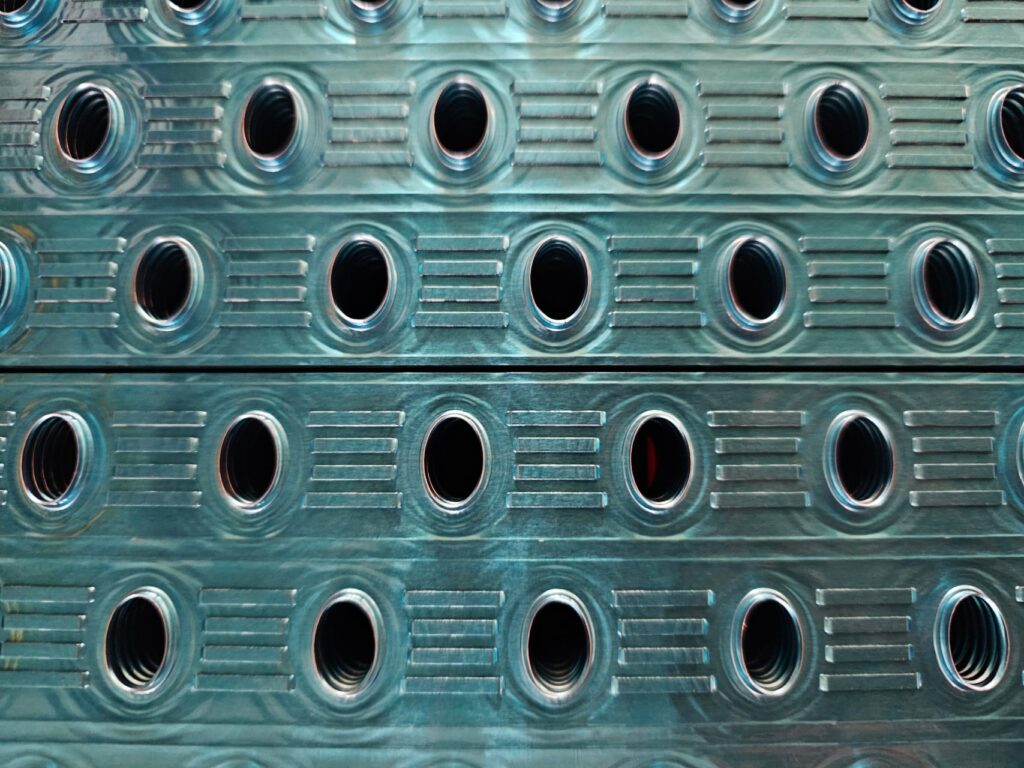

Versatile Applications: Ideal for various industries, including HVAC, automotive, and aerospace, our Vertical Tube Expander can handle a wide range of tube sizes and materials.

Applications

HVAC Industry: Perfect for expanding tubes used in heating, ventilation, and air conditioning systems, ensuring efficient heat transfer and reliable performance.

Automotive Sector: Ideal for producing high-quality tubes required in vehicle exhaust systems and other automotive applications.

Aerospace: Ensures precise expansion of tubes used in critical aerospace components, maintaining the highest standards of safety and performance.

Why Choose SINOAK?

Innovation: At SINOAK, we are committed to continuous innovation, providing you with the latest technology in tube expansion.

Expert Support: Our team of experts offers comprehensive support, from installation to maintenance, ensuring your machinery operates at peak performance.

Customer Satisfaction: We prioritize customer satisfaction by delivering reliable and high-performance equipment tailored to meet your specific needs.

Contact Us

For more information on SINOAK’s Stainless Steel Vertical Tube Expander, visit our Contact Page or reach out directly at [email protected].

Stay connected with us on WhatsApp and WeChat: +86 15688803399

Explore More

Learn about our other high-quality products:

Stay updated with the latest in manufacturing technology by visiting ASHRAE and following industry news on ACHR News.