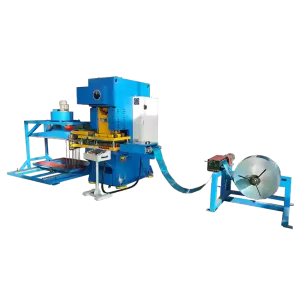

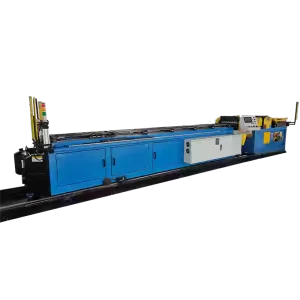

Semi-Automatic Hairpin Bender for Efficient Heat Exchanger Production

Detailed Description

SINOAK’s Semi-Automatic Hairpin Bender is a revolutionary addition to the heat exchanger manufacturing industry. Engineered to optimize production processes, this advanced machine provides an array of benefits for our clients.

Features

Precision Bending:

The Semi-Automatic Hairpin Bender by SINOAK excels in creating hairpin-shaped tubes with precise and consistent bends. This level of accuracy is crucial for ensuring the efficiency and effectiveness of heat exchangers.

Efficiency Enhancement:

By automating the bending process, this machine significantly reduces production time, resulting in accelerated output and reduced labor costs. It’s the perfect solution for meeting demanding production schedules.

Reliability:

SINOAK is committed to delivering reliable equipment, and our Hairpin Bender is no exception. Its robust construction and top-quality components guarantee long-lasting performance with minimal downtime.

Customer Benefits

Increased Efficiency:

Our Semi-Automatic Hairpin Bender automates labor-intensive tasks, boosting efficiency and reducing production time. This results in higher output and decreased operational costs.

Precision & Consistency:

With accurate bending capabilities, you can count on each hairpin tube to meet exact specifications, enhancing the overall quality of your heat exchangers.

Reliability:

SINOAK’s reputation for dependable machinery extends to our Semi-Automatic Hairpin Bender. You can rely on it for consistent performance and longevity.

SINOAK’s Advantages

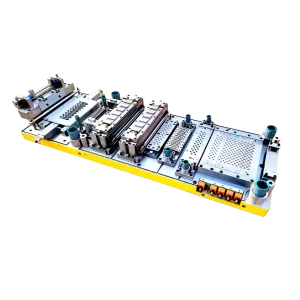

Customization:

We understand that each client’s needs are unique. SINOAK can customize the Semi-Automatic Hairpin Bender to meet specific requirements, whether it’s tube diameter, bending radius, or any other aspect.

Technical Expertise:

Our team of engineers and technicians boasts a wealth of experience in the field, ensuring you receive cutting-edge technology and expert support.

Reliability:

With SINOAK, you’re not just acquiring a machine; you’re investing in a long-term partnership. We stand by our products and provide comprehensive after-sales support.

Technical Specifications

| Item | Specification |

|---|---|

| Model | SKBW-4, SKBW-5 |

| Max Number of Bending | 4 mm, 5 mm |

| Pipe Diameter | φ5-φ15.88 mm |

| Thickness Range | 0.25-0.8 mm |

| Center Distance | According to the fin drawing |

| Min. Bending Length | 200 mm |

| Max. Bending Length | 3000 mm |

| Cycle | ≤12 S (According to the workpiece 1m long) |

| Feeding Mode | By hand |

Application Scenario

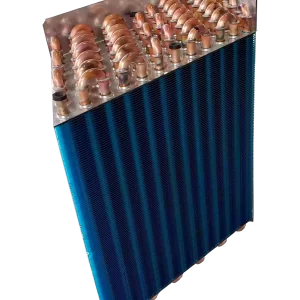

Our Semi-Automatic Hairpin Bender is essential for various industrial applications, especially in the production of heat exchangers. Whether you are manufacturing air conditioning units, refrigeration systems, or automotive heat exchangers, our advanced bending machine ensures efficient and precise production.

For more information on our Fin Dies and Tube Expanders, visit our website. To learn more about advancements in heat exchanger technology, explore ASHRAE and HVACR News.

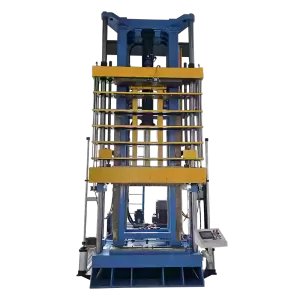

Explore more on our main website to find additional information on our Fully Automatic U-Bending Machines and Vertical Expanders.

Contact Us for Semi-Automatic Hairpin Bender Solutions

Stay connected with us on WhatsApp and WeChat: +86 15688803399

If you have any questions or need further assistance, feel free to contact us at [email protected].

View Related Videos:

Reviews

There are no reviews yet.