Discover Precision with SINOAK’s H-Type Fin Press Line

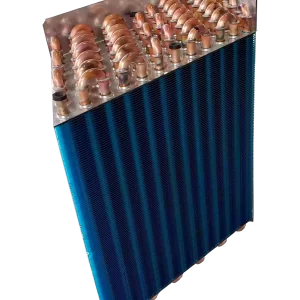

Discover the next level of precision in heat exchanger fin production with SINOAK’s Fin Press Line (H-type). Our innovative H-type technology ensures accuracy and efficiency in every fin pressed, elevating the overall performance of heat exchangers.

Benefits

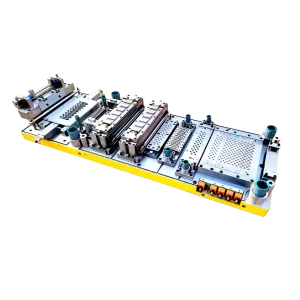

Precision Fin Pressing:

Our H-type technology guarantees precise and uniform fin pressing, optimizing heat exchanger efficiency.

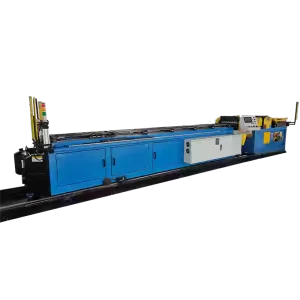

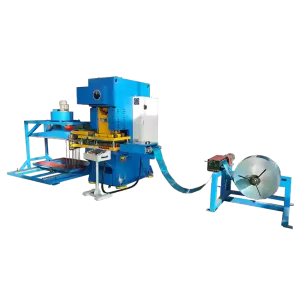

Advanced Machinery:

Explore the cutting-edge features of SINOAK’s Fin Press Line, designed for reliability and high-performance manufacturing.

Customization Options:

Tailor the Fin Press Line to meet your specific production requirements, ensuring flexibility in your manufacturing processes.

Efficient Production:

Increase productivity with our advanced machinery, streamlining your heat exchanger fin production.

Why Choose SINOAK

Innovative Technology:

SINOAK Machinery is at the forefront of innovation, bringing you advanced solutions for heat exchanger manufacturing.

Reliability:

Trust in the reliability of our machinery, designed to meet the rigorous demands of the industry.

Customization:

We understand the unique needs of manufacturers. Our Fin Press Line offers customization options to align with your specific requirements.

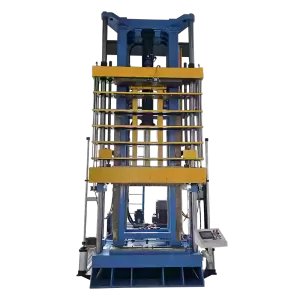

Technical Specifications

| Model | GSK60P | GSK100-36P | GSK160P/GC200P |

|---|---|---|---|

| Capacity (KN) | 600 | 1000 | 1600/2000 |

| Stroke (mm) | 40 | 50 | 60 |

| Press Speed (spm) | 150~300 | 150~290 | 150~250 |

| Die Height (mm) | 270~320 | 270~320 | 270~320 |

| Die Height Adjustment (max) (mm) | 150 | 200 | 200 |

| Slide Size (mm) | 900×850 | 1160×1300 | 1150×1300 |

| Bolster Size (mm) | 880×1040 | 1190×1320 | 1190×1320 |

| Bolster Size (max) (mm) | 880×1460 | 1190×1740 | 1190×1740 |

| Main Motor (KW) | 7.5 | 11 | 18.5/22 |

| Total Power (KW) | 18.5 | 22 | 29.5/34 |

| Air Pressure (Mpa) | 0.55-0.75 | 0.55-0.75 | 0.55-0.75 |

| Hydraulic Pressure (Mpa) | 10 | 10 | 12.5/15.8 |

| ID of Aluminum (mm) | Φ150 | Φ150 | Φ150/Φ480 |

| OD of Aluminum (max) (mm) | Φ1000 | Φ1200 | Φ1200 |

| Width of Aluminum (max) (mm) | 550 | 850 | 850 |

| Height of Collecting (max) (mm) | 750/900 | 750/900 | 750/900 |

| Total Weight (Ton) | 18 | 23 | 25 |

Application Scenario

Our H-Type Fin Press Line is ideal for producing high-quality fins for various heat exchanger applications, including air conditioning, refrigeration, and automotive radiators. With our advanced machinery, you can achieve optimal performance and efficiency in your production processes.

For more detailed information about our products and their applications, visit our main website. Check out our Semi-Automatic Hairpin Bender and Fully Automatic U-Bending Machine.

Why Choose SINOAK’s Fin Press Line

Innovative Technology:

Our fin press line incorporates the latest technology to provide precise control and seamless process integration. Learn more about our advanced Tube Expanders and Vertical Expanders.

Customization:

We offer tailored solutions to meet your specific production needs. Whether you need unique configurations or specific functionalities, our team can customize the H-Type Fin Press Line to align perfectly with your requirements.

Reliability and Durability:

Our equipment is built to last, ensuring long-term performance and minimal downtime. This robust construction is vital for maintaining efficiency in demanding industrial environments.

Comprehensive Support:

SINOAK provides comprehensive support, from initial consultation to after-sales service. Explore more about our Fin Dies and other products.

Contact Us for H-Type Fin Press Line Solutions

Stay connected with us on WhatsApp and WeChat: +86 15688803399

If you have any questions or need further assistance, feel free to contact us at [email protected].

External Links

For more information on advancements in heat exchanger technology, visit ASHRAE and stay updated with industry news on ACHR News.

Reviews

There are no reviews yet.