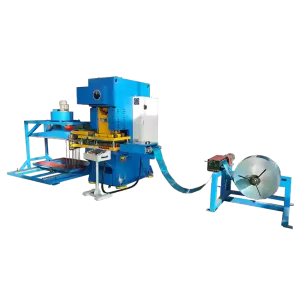

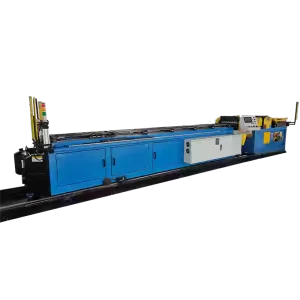

CNC Coil Bender for Efficient Heat Exchanger Production

Streamlining Heat Exchanger Manufacturing

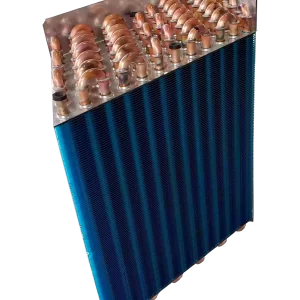

Discover how SINOAK’s CNC Coil Bender revolutionizes heat exchanger production. This pivotal machine excels in bending fins into versatile shapes, including L, U, and G configurations. This versatility allows for easy installation in limited spaces, ensuring optimal heat exchanger performance.

At SINOAK Machinery, we offer advanced CNC Coil Benders designed to meet the demanding needs of heat exchanger manufacturers. Our equipment is engineered for precision and efficiency, enabling you to produce heat exchangers of the highest quality. Discover the advantages of our CNC Coil Benders and take your heat exchanger production to the next level.

Benefits

Efficient Fin Bending:

Our CNC Coil Bender efficiently bends fins into L, U, or G shapes, catering to various design requirements.

Space Optimization:

The ability to bend fins into different shapes allows for space optimization during heat exchanger installation, enhancing overall performance.

Enhanced Performance:

By using our advanced CNC Coil Benders, you can ensure enhanced heat exchanger performance, leading to better energy efficiency.

SINOAK Quality:

Rely on SINOAK’s reputation for delivering high-quality, advanced machinery that meets the stringent demands of heat exchanger production.

Technical Specifications

| Item | Specification |

|---|---|

| Model | SKZL-1200, SKZL-1500, SKZL-2000, SKZ-800, SKZ-1200, SKZ-1500 |

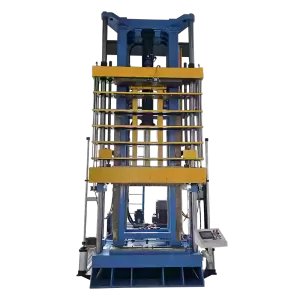

| Structure | Column type, Cantilever type |

| Power | Servo/Hydraulic |

| Number of Bending Layers | 1-3 |

| Bend Angle | 0°-120° |

| Bend Radius (mm) | Provided by the Customer |

| Pipe Diameter (mm) | Provided by the Customer |

| Layer Spacing | Provided by the Customer |

| Max Working Width (mm) | 1200, 1500, 2000, 800, 1200, 1500 |

| Work Efficiency (S) | Bend one time ≤15, L-Type Each ≤30, U-Type Each ≤60, G-Type Each ≤90 |

| Total Power (K) | 3, 4.5 |

| Air Pressure (Mpa) | 0.4-0.7 |

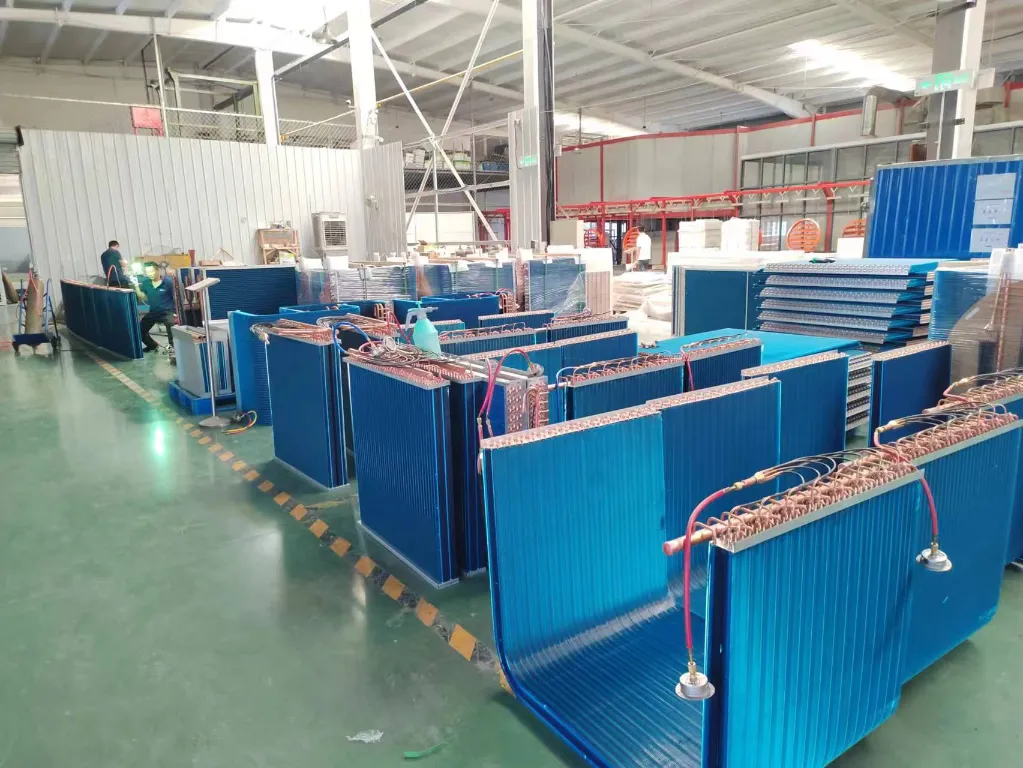

Application Scenario

Our CNC Coil Benders are essential in various industrial applications, particularly in the production of heat exchangers. Whether you are manufacturing air conditioning units, refrigeration systems, or automotive heat exchangers, our advanced CNC Coil Benders ensure precise and efficient production.

For more information on our CNC Coil Benders, visit our Bending Machines page. If you have any questions or need further assistance, feel free to contact us at [email protected].

Stay connected with us on WhatsApp and WeChat: +86 15688803399

Further Exploration

Learn more about our advanced solutions:

- For detailed information on our Tube Expanders.

- Explore our Vertical Expanders for efficient tube expansion.

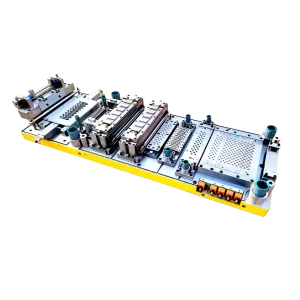

- Discover our Fin Dies for high-precision fin production.

Stay informed with the latest advancements in heat exchanger technology by visiting ASHRAE and keep up with industry news on ACHR News.

View Related Videos:

Reviews

There are no reviews yet.