Cold Storage Evaporator Video Content

Video Title

“Cold Storage Evaporators by SINOAK: Precision & Efficiency in Cooling”

Video Description

Discover SINOAK’s advanced Cold Storage Evaporator production process. Our state-of-the-art equipment ensures top-notch efficiency and precision in manufacturing high-quality evaporators for cold storage applications. Learn more at sinoak.com and stay connected on WhatsApp and WeChat: +86 15688803399.

Video Script

[Opening Scene]

Shot of SINOAK’s logo and a bustling factory floor.

Narrator: “Welcome to SINOAK, where innovation meets efficiency in the manufacturing of cold storage evaporators.”

[Scene 2: Machine in Action]

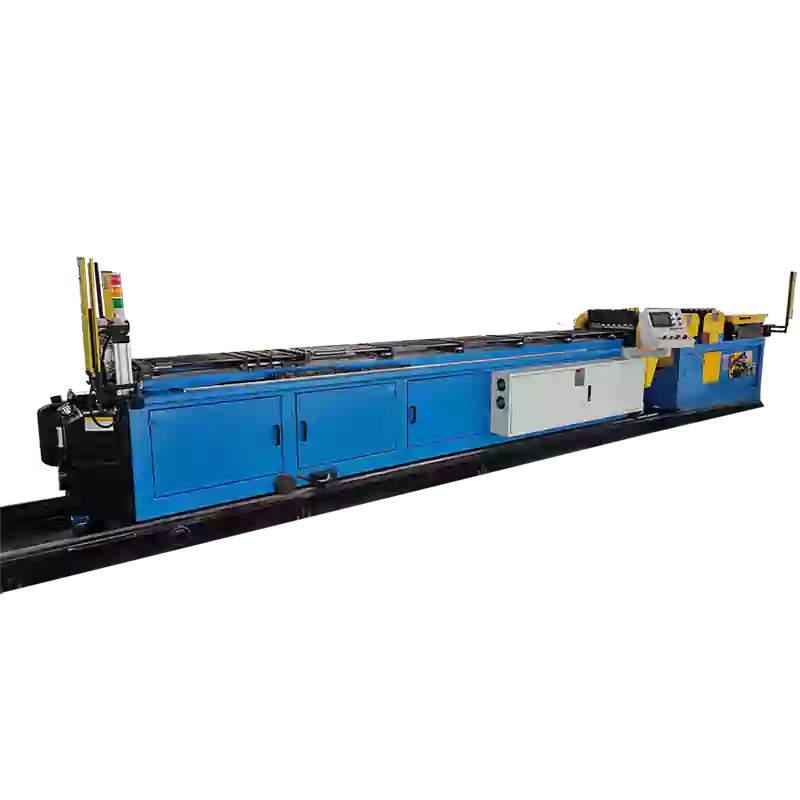

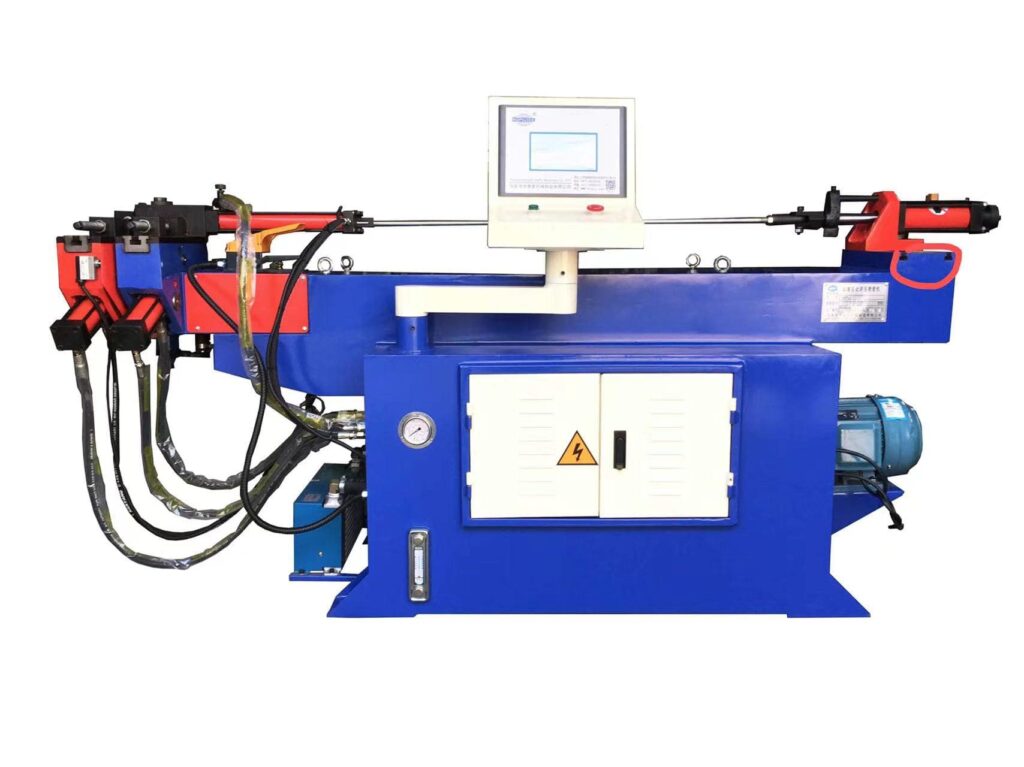

Close-up shots of the Cold Storage Evaporator production line, highlighting various stages of the process.

Narrator: “Our Cold Storage Evaporator production line utilizes cutting-edge technology to deliver unparalleled precision and quality.”

[Scene 3: Key Features]

Text overlay with key features: Precision Engineering, High Efficiency, Durable Construction.

Narrator: “Engineered for precision and efficiency, our evaporators are built to last, ensuring optimal performance in cold storage environments.”

[Scene 4: Customer Testimonials]

Short clips of satisfied customers discussing their experience with SINOAK’s products.

Customer 1: “SINOAK’s evaporators have significantly improved our cold storage efficiency.”

Customer 2: “The durability and performance are outstanding. We couldn’t be happier.”

[Scene 5: Closing Scene]

Shot of a finished Cold Storage Evaporator being inspected.

Narrator: “Trust SINOAK for all your cold storage evaporator needs. Contact us today to learn more.”

[Outro]

Display contact information and website link.

Narrator: “Visit us at sinoak.com and stay connected on WhatsApp and WeChat: +86 15688803399.”

Cold Storage Evaporator Webpage Content

Page Title

“Cold Storage Evaporators | High-Efficiency Cooling Solutions by SINOAK”

Meta Description

“Explore SINOAK’s high-efficiency cold storage evaporators, designed for optimal performance and durability in cold storage applications. Contact us to learn more.”

Header

High-Efficiency Cold Storage Evaporators

Introduction

Welcome to SINOAK’s Cold Storage Evaporators page. Our advanced evaporators are engineered to meet the demanding needs of cold storage applications, ensuring high efficiency and reliability. Whether you need solutions for refrigerated warehouses, food processing plants, or cold rooms, SINOAK’s evaporators are designed to deliver optimal cooling performance.

Key Features

Precision Engineering

Our evaporators are crafted with precision engineering to ensure optimal performance and longevity.

High Efficiency

Designed for maximum efficiency, our evaporators reduce energy consumption while maintaining high performance.

Durable Construction

Built with high-quality materials, SINOAK’s evaporators are durable and reliable, perfect for the rigorous demands of cold storage environments.

Technical Specifications

| Item | Specification |

|---|---|

| Model | CS-EV-100, CS-EV-200, CS-EV-300 |

| Cooling Capacity | 10kW, 20kW, 30kW |

| Refrigerant | R404A, R134a, R507 |

| Fin Material | Aluminum, Copper |

| Tube Material | Copper, Stainless Steel |

| Fin Spacing | 4mm, 6mm, 8mm |

| Dimensions | Customizable |

| Weight | Depending on model |

Applications

Our Cold Storage Evaporators are ideal for:

Refrigerated Warehouses:

Ensuring consistent cooling for large storage spaces.

Food Processing Plants:

Maintaining optimal temperatures for food safety and quality.

Cold Rooms:

Providing reliable cooling for various storage needs.

Customer Testimonials

“Switching to SINOAK’s evaporators has drastically improved our cold storage efficiency.” – John D.

“The reliability and performance of these evaporators are unmatched.” – Sarah K.

Contact Us

For more information on our Cold Storage Evaporators, visit our Contact Page or reach out to us directly at [email protected].

Stay connected with us on WhatsApp and WeChat: +86 15688803399

Explore More

Learn about our other products:

Stay updated with the latest in heat exchanger technology by visiting ASHRAE and following industry news on ACHR News.