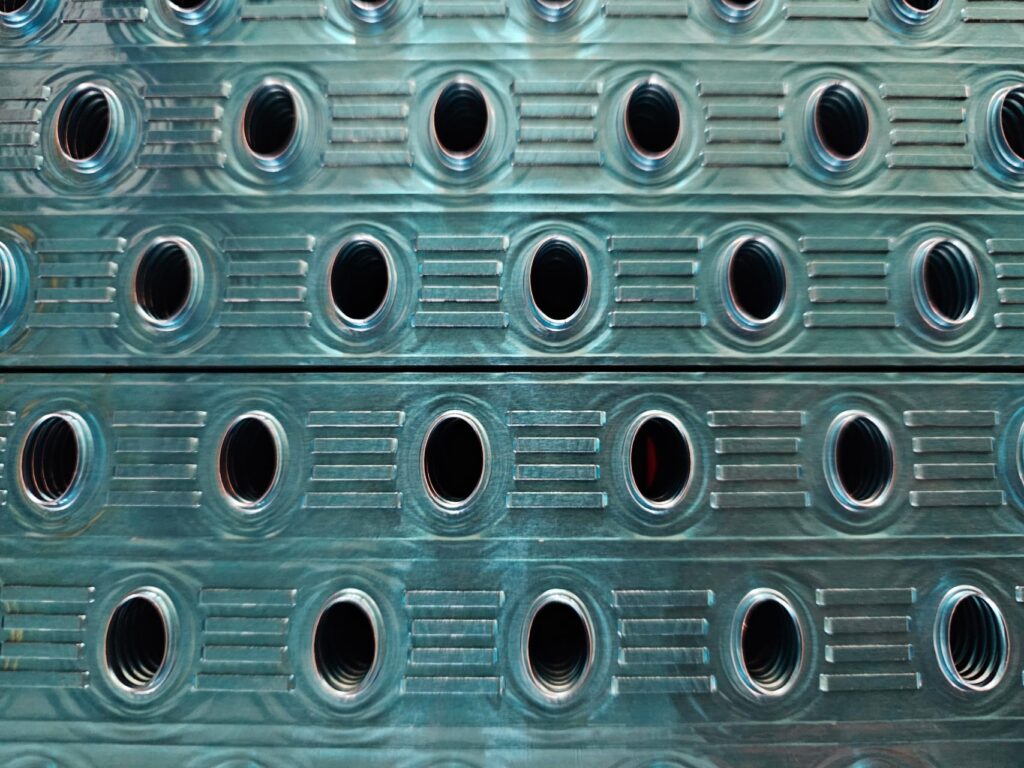

Heat Exchanger with Elliptical Orifice by SINOAK

Introduction

Welcome to SINOAK’s Heat Exchanger with Elliptical Orifice page. Our advanced heat exchangers are designed to provide superior thermal performance and efficiency. The elliptical orifice design ensures optimal heat transfer, making it ideal for various industrial applications.

Key Features of SINOAK’s Heat Exchanger with Elliptical Orifice

Enhanced Heat Transfer:

The elliptical orifice design significantly enhances heat transfer efficiency compared to traditional round orifices. This design ensures more effective cooling and heating processes.

Durable Construction:

Built with high-quality materials, our heat exchangers guarantee durability and long-term reliability, even in the most demanding industrial environments.

Versatility:

SINOAK’s heat exchangers are suitable for a wide range of applications, including HVAC systems, industrial cooling, and heating systems. This versatility makes it an ideal choice for manufacturers seeking reliable heat transfer solutions.

Customizable Design:

Our heat exchangers can be customized to meet specific requirements, including size, material, and orifice design. This flexibility ensures that our products meet the unique needs of each client.

Applications of SINOAK’s Heat Exchanger with Elliptical Orifice

SINOAK’s heat exchangers are perfect for:

- HVAC Systems: Enhancing cooling and heating efficiency in residential and commercial buildings.

- Industrial Cooling: Providing reliable cooling solutions for various industrial processes.

- Heating Systems: Optimizing heat transfer in industrial and residential heating applications.

- Automotive Industry: Improving the performance of automotive radiators and cooling systems.

Technical Specifications

| Item | Specification |

|---|---|

| Orifice Design | Elliptical |

| Material | Aluminum, Copper, Stainless Steel |

| Heat Transfer Area | Customizable according to client requirements |

| Efficiency | Enhanced heat transfer efficiency |

| Durability | High-quality construction for long-term reliability |

Why Choose SINOAK’s Heat Exchanger with Elliptical Orifice

Innovative Design:

Our heat exchangers utilize the latest design innovations to ensure superior performance and efficiency. The elliptical orifice design maximizes heat transfer capabilities, setting our products apart from traditional designs.

Customization Options:

We offer tailored solutions to meet your specific needs. Whether you require a particular size, material, or orifice design, our team can customize the heat exchanger to align perfectly with your requirements.

Reliability and Durability:

Our heat exchangers are built to withstand the rigors of industrial use, ensuring long-term performance with minimal maintenance. This reliability is crucial for maintaining high efficiency in various applications.

Customer Testimonials

“SINOAK’s heat exchangers have greatly improved our system efficiency. The elliptical orifice design is a game-changer,” says David M.

“The durability and performance of SINOAK’s heat exchangers are exceptional. We highly recommend their products,” remarks Lisa T.

Contact Us for Heat Exchanger Solutions

For more information on our heat exchangers, visit our Contact Page or reach out to us directly at [email protected].

Stay connected with us on WhatsApp and WeChat: +86 15688803399

Explore More

Learn about our other high-quality products:

- Tube Expanders: Advanced solutions for efficient heat exchanger production.

- Vertical Expanders: Precision machines designed for accurate tube expansion.

- Fin Dies: Explore our range for top-quality fin production.

Stay updated with the latest in manufacturing technology by visiting ASHRAE and following industry news on ACHR News.