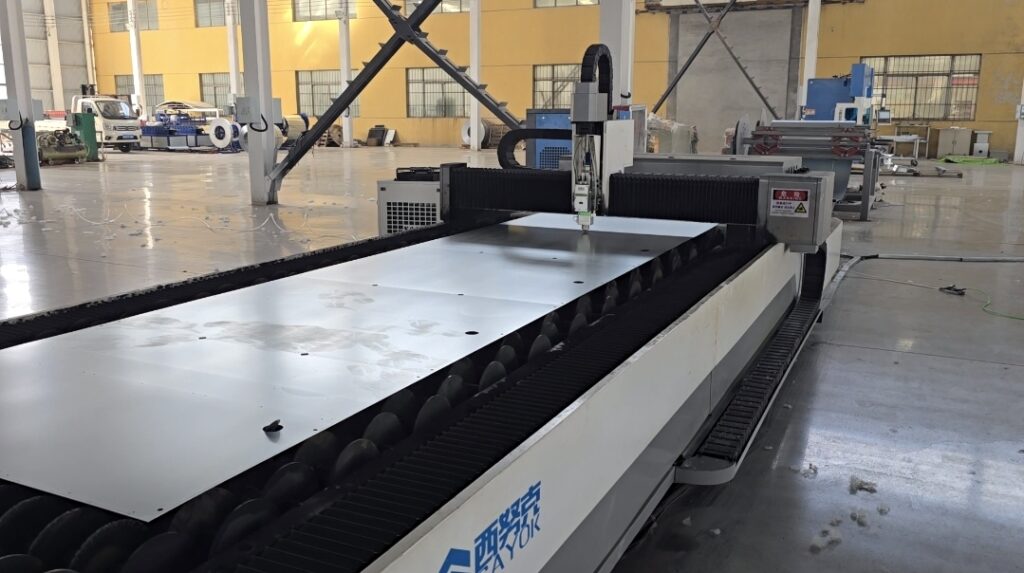

Laser Cutting Machine – High Precision and Efficiency by SINOAK

Introduction

Welcome to SINOAK’s Laser Cutting Machine page. Our state-of-the-art laser cutting technology offers unparalleled accuracy and speed, meeting the diverse needs of modern manufacturing industries. Whether you are cutting metals, plastics, or other materials, SINOAK’s laser cutting solutions ensure precision and efficiency.

Key Features of SINOAK’s Laser Cutting Machine

High Precision:

SINOAK’s machine delivers high-precision cuts with minimal tolerance, ensuring each piece meets exact specifications. This precision is essential for applications requiring detailed and intricate designs.

Efficiency and Speed:

Our laser cutting machine offers high-speed cutting capabilities, significantly reducing production time. This efficiency helps in meeting tight deadlines and increasing overall productivity.

Versatility:

Designed to handle various materials, including metals, plastics, and composites, SINOAK’s laser cutting machine is suitable for multiple industrial applications. This versatility makes it an ideal choice for manufacturers seeking flexible cutting solutions.

User-Friendly Interface:

Equipped with an intuitive control panel, our machine allows for easy operation and programming. The user-friendly interface ensures operators can quickly set up and manage cutting tasks with minimal training.

Durable Construction:

Built with robust materials and components, SINOAK’s laser cutting machine guarantees long-term reliability and durability. This construction ensures consistent performance even under demanding industrial conditions.

Applications of SINOAK’s Machine

SINOAK’s machine is perfect for:

- Automotive Industry: Cutting metal parts and components with high precision.

- Aerospace: Fabricating intricate components for aircraft and spacecraft.

- Electronics: Creating precise cuts for circuit boards and electronic enclosures.

- Metal Fabrication: Producing custom metal parts and structures.

- Signage and Advertising: Cutting detailed designs for signs and displays.

Technical Specifications

| Item | Specification |

|---|---|

| Laser Power | 500W to 3000W |

| Cutting Speed | Up to 100 m/min |

| Cutting Accuracy | ±0.01mm |

| Material Thickness | Up to 25mm (varies with material) |

| Work Area | Customizable according to client requirements |

| Control System | Advanced CNC control with touchscreen interface |

| Cooling System | Integrated water cooling system |

Why Choose SINOAK’s Laser Cutting Machine

Advanced Technology:

We incorporate the latest laser cutting technologies to ensure superior performance and accuracy. Our commitment to innovation ensures you receive the best cutting solutions for your manufacturing needs.

Customization Options:

SINOAK offers tailored solutions to meet your specific production requirements. Whether you need a unique work area or specific laser power, our team can customize the machine to align perfectly with your needs.

Reliability and Durability:

Our laser cutting machines are built to withstand the rigors of industrial use, ensuring long-term performance with minimal maintenance. This reliability is vital for maintaining high efficiency in production environments.

Customer Testimonials

“SINOAK’s machine has revolutionized our production process. The precision and speed are unmatched,” says John D.

“We are extremely satisfied with the performance and durability of SINOAK’s equipment. It has significantly improved our production capabilities,” remarks Sarah T.

Contact Us for Laser Cutting Machine Solutions

For more information on our machines, visit our Contact Page or reach out to us directly at [email protected].

Stay connected with us on WhatsApp and WeChat: +86 15688803399

Explore More

Learn about our other high-quality products:

- Tube Expanders: Advanced solutions for efficient heat exchanger production.

- Vertical Expanders: Precision machines designed for accurate tube expansion.

- Fin Dies: Explore our range for top-quality fin production.

Stay updated with the latest in manufacturing technology by visiting ASHRAE and following industry news on ACHR News.