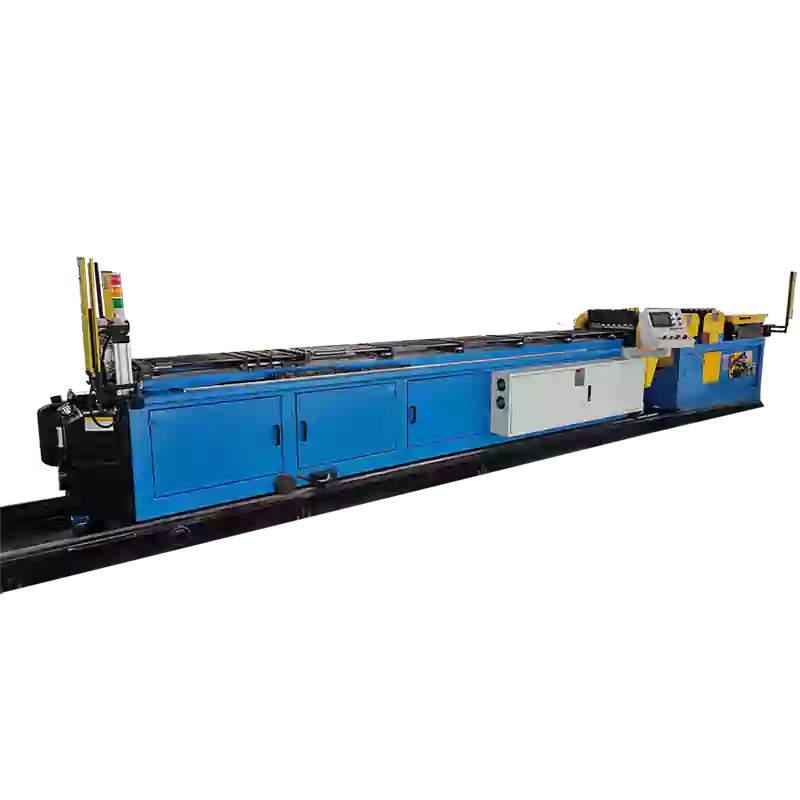

SINOAK Hairpin Bender: 8 Years of Unmatched Performance

Welcome to the showcase of SINOAK’s enduring Hairpin Bender. This exceptional machine has demonstrated consistent performance and reliability over the past eight years, proving its value in the heat exchanger manufacturing industry.

Key Features

Precision Engineering

SINOAK’s Hairpin Bender is engineered for precision. Each hairpin bend is accurate and consistent, maintaining the integrity and efficiency of heat exchangers.

High Efficiency

The machine optimizes the bending process, reducing production time and labor costs. Its automated operations ensure high-speed production without compromising quality.

Robust Durability

Constructed from high-quality materials, the Hairpin Bender withstands rigorous industrial use. Its durability ensures long-term reliable performance, making it a cost-effective solution for manufacturing needs.

Applications

- HVAC Systems: Enhances the efficiency and reliability of heating, ventilation, and air conditioning systems.

- Automotive Industry: Ensures accurate bends in heat exchanger components for automotive applications.

- Refrigeration Systems: Provides consistent bends for refrigeration coils, improving performance and longevity.

Technical Specifications

| Item | Specification |

|---|---|

| Model | HB-100, HB-200 |

| Pipe Diameter Range | 6mm to 50mm |

| Bending Angle | 0° to 180° |

| Material Compatibility | Copper, Aluminum, Stainless Steel |

| Bending Speed | Adjustable up to 50 bends per minute |

| Control System | PLC with touch screen interface |

| Power Supply | 220V/380V, 50/60Hz |

| Dimensions | Customizable according to client requirements |

| Weight | Varies based on model and customization options |

Why Choose SINOAK

Innovative Technology

Leveraging cutting-edge technology, SINOAK provides state-of-the-art solutions for pipe bending. Our Hairpin Bender reflects our commitment to innovation and quality.

Customization Options

We offer tailored solutions to meet your specific production needs. Whether you require unique configurations or specific functionalities, our team can customize the Hairpin Bender to align perfectly with your requirements.

Reliability and Durability

Our equipment is built to last, ensuring long-term performance and minimal downtime. This robust construction is vital for maintaining efficiency in demanding industrial environments.

Customer Testimonials

“Using SINOAK’s Hairpin Bender has significantly improved our production efficiency,” says Alex P.

“The precision and durability of this bender are unmatched. We couldn’t be happier with our choice,” remarks Maria L.

Contact Us

For more information on our Hairpin Bender, visit our Contact Page or reach out to us directly at [email protected].

Stay connected with us on WhatsApp and WeChat: +86 15688803399

Explore More

Learn about our other high-quality products:

- 8-Tube Expanding Machine: Explore our range for top-quality tube expansion.

- Fin Production Line: Discover our advanced fin production line for precise fin manufacturing.

- Heat Exchanger: Comprehensive solutions for heat exchanger manufacturing.

Stay updated with the latest in manufacturing technology by visiting ASHRAE and following industry news on ACHR News.