Your Reliable Heat Exchanger Equipment Manufacturer

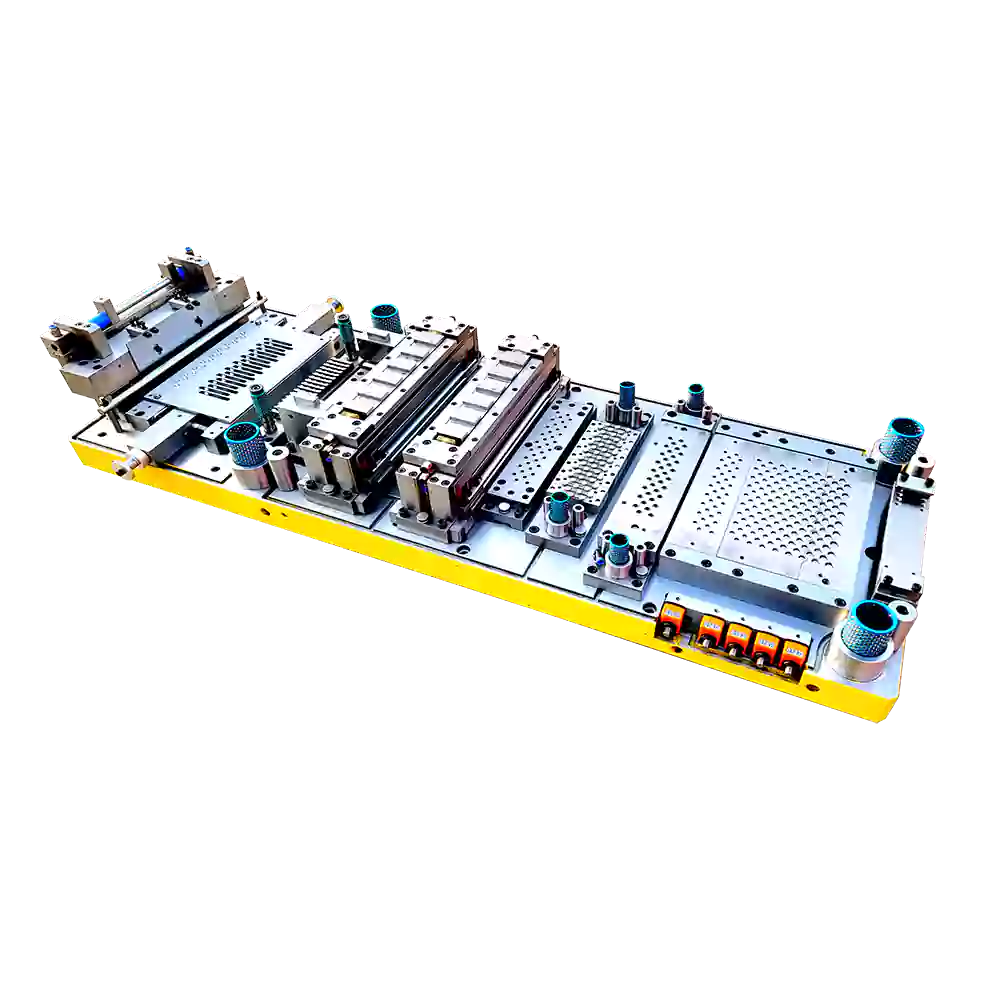

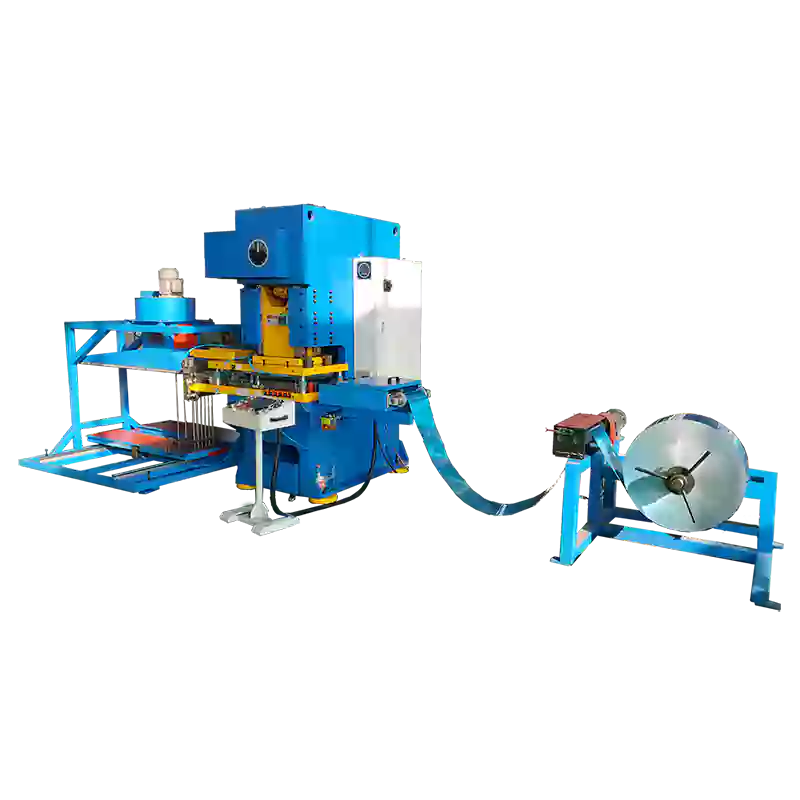

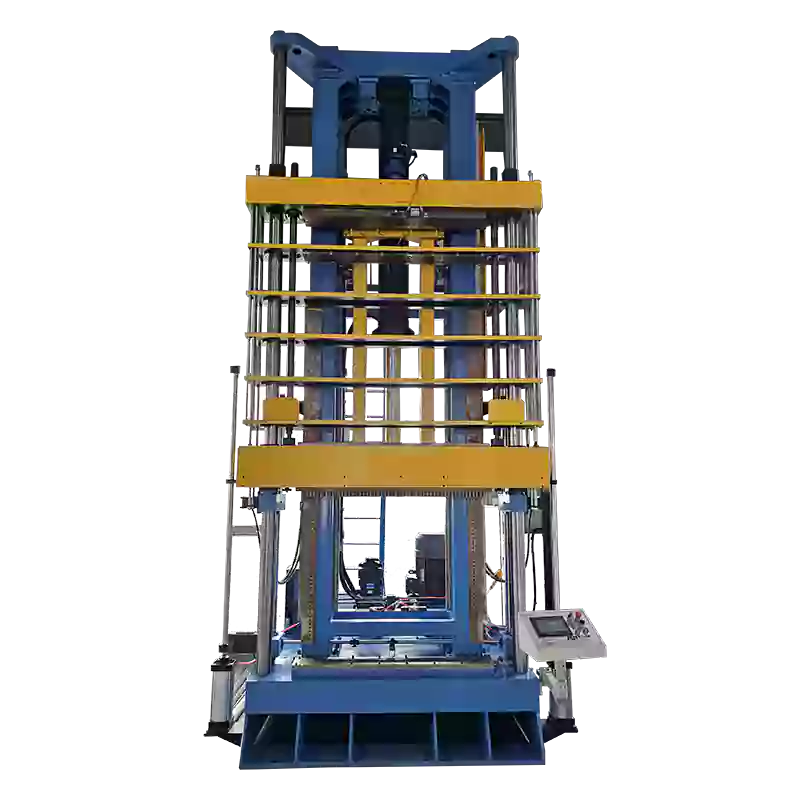

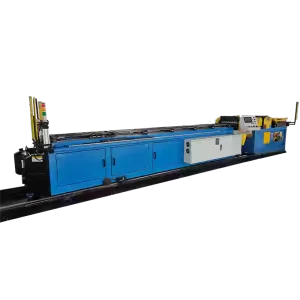

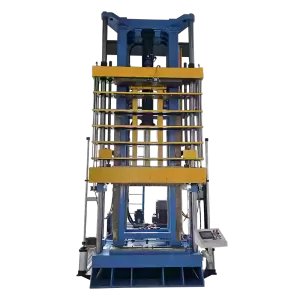

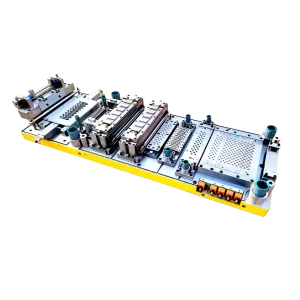

SHANDONG SINOAK CO., LTD.founded in 2008 in Dezhou, Shandong, is your trusted provider of custom heat exchanger equipment. We specialize in crafting precise solutions tailored to various industries, supporting efficient and high-quality manufacturing.

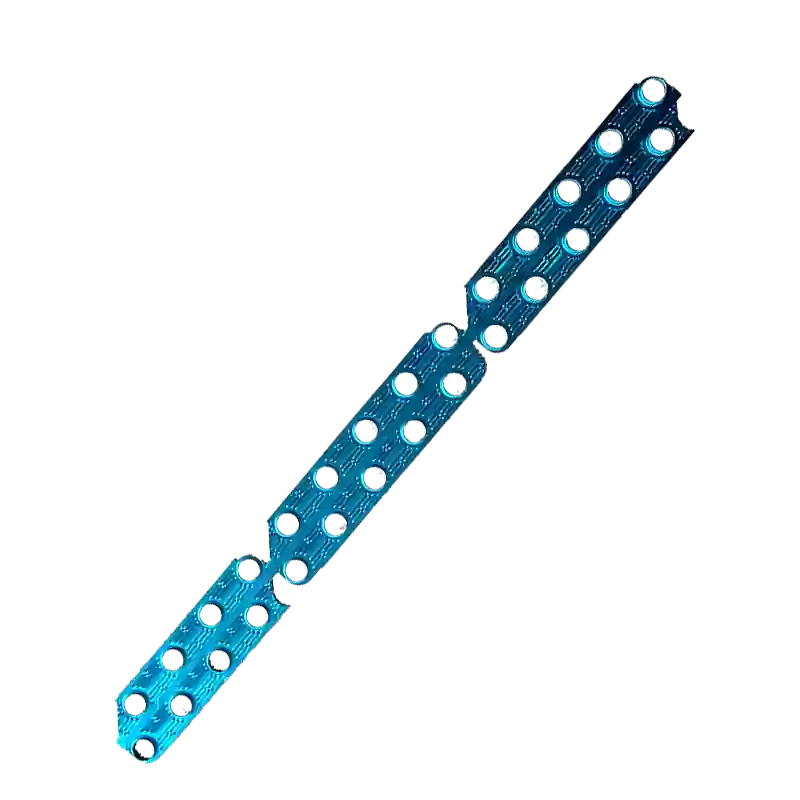

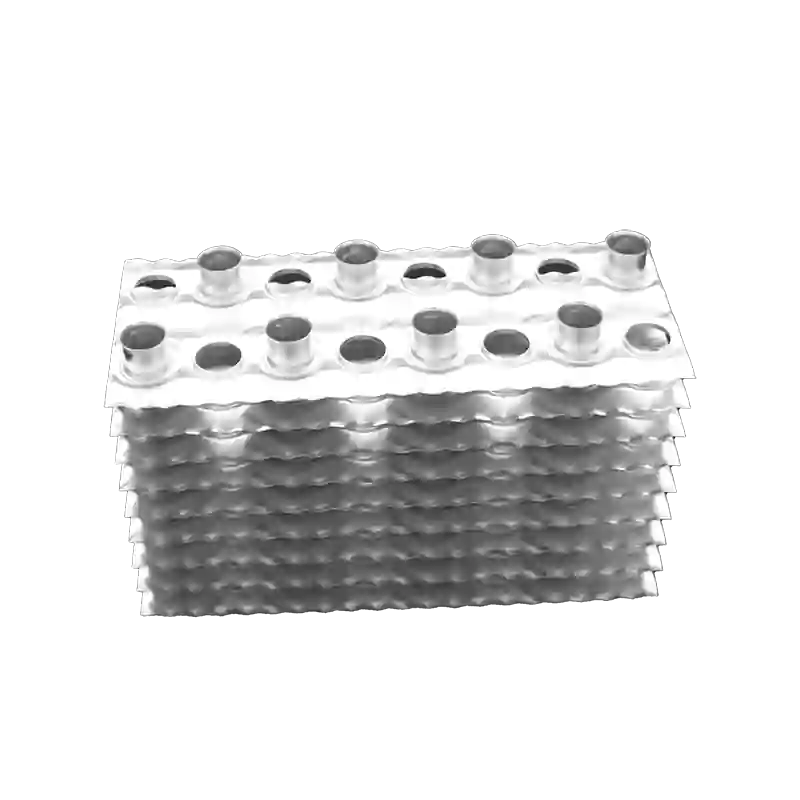

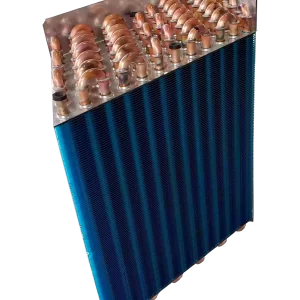

Versatile Applications: Our equipment finds applications in refrigeration, automotive, cold storage, agriculture, solar energy, and heat pumps. We offer customized solutions to meet unique sector needs.

Quality Priority: SINOAK prioritizes quality. Our Dezhou facility ensures machines meet top performance and durability standards, enhancing your production efficiency and product reliability.

Trusted Partner: With over a decade of experience, SINOAK is renowned for excellence and reliability. We’re committed to innovation and customer satisfaction, empowering your business with cutting-edge solutions.

Choose SINOAK for precision and customization in heat exchanger equipment. Unlock new possibilities with SINOAK today.

Send Inquiry