Types of Fin Dies

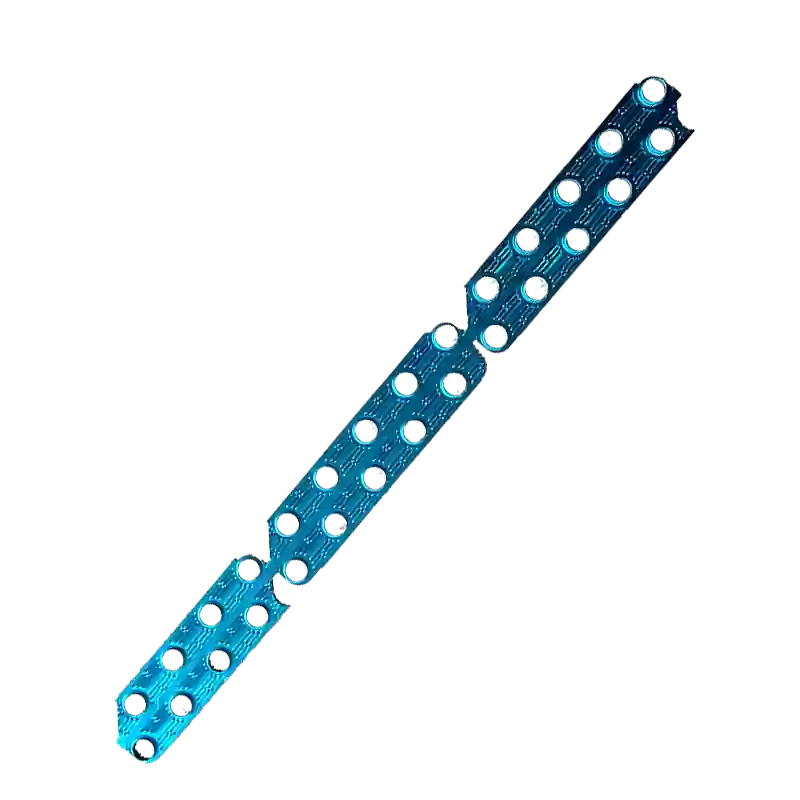

Wave Fin Dies:

Wave fin dies have a distinctive wavy pattern, making them ideal for air conditioning units and refrigerators. This wave design increases the space between fins, thereby optimizing heat transfer and improving cooling efficiency.

High Collar Fin Dies:

High collar edge fin dies cater to applications requiring defrosting, such as commercial refrigeration. These fins feature electric heating holes along their edges to facilitate the defrosting process.

V-Waffle Fin Dies:

V-waffle fin dies have a V-shaped pattern, which makes them perfect for heat exchangers in the automotive industry. The V-waffle design enhances turbulence and heat transfer, thus improving radiator performance.

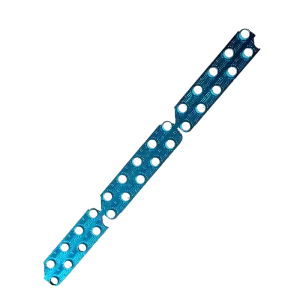

Louver Fin Dies:

Louver fin dies create fins with angled blades. Consequently, they are commonly used in residential air conditioning systems, enhancing the efficiency of heat transfer and air circulation.

Sine Wave Fin Dies:

Sine wave fin dies produce fins with a sinusoidal pattern. Manufacturers often use them in the production of heat sinks for electronics, providing efficient cooling and heat dissipation.

Applications of Fin Dies

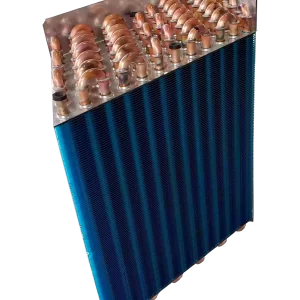

Air Conditioning:

Fin dies play a crucial role in producing air conditioning units. They create the fins needed for heat exchangers, thereby enhancing cooling efficiency.

Refrigeration:

In refrigeration equipment, such as refrigerators and commercial freezers, fin dies manufacture fins that ensure efficient heat dissipation and temperature control.

Automotive Radiators:

Automotive radiators rely on fin dies to create heat exchanger fins, which contributes to efficient engine cooling.

Electronics:

Manufacturers use fin dies to produce heat sinks for electronic components, such as computer CPUs and power supplies. These fins help electronic devices maintain optimal operating temperatures.

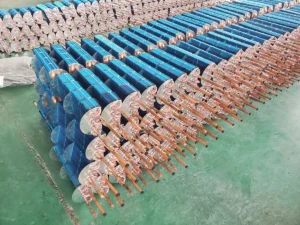

Solar Water Heaters:

Fin dies are essential in manufacturing solar water heaters, enhancing heat absorption and transfer, thus improving energy efficiency.

SINOAK excels in producing various types of fin dies for these applications. Their expertise and high-precision manufacturing ensure that customers receive top-quality fin dies tailored to their specific needs. As a result, performance and efficiency are enhanced across diverse industries.

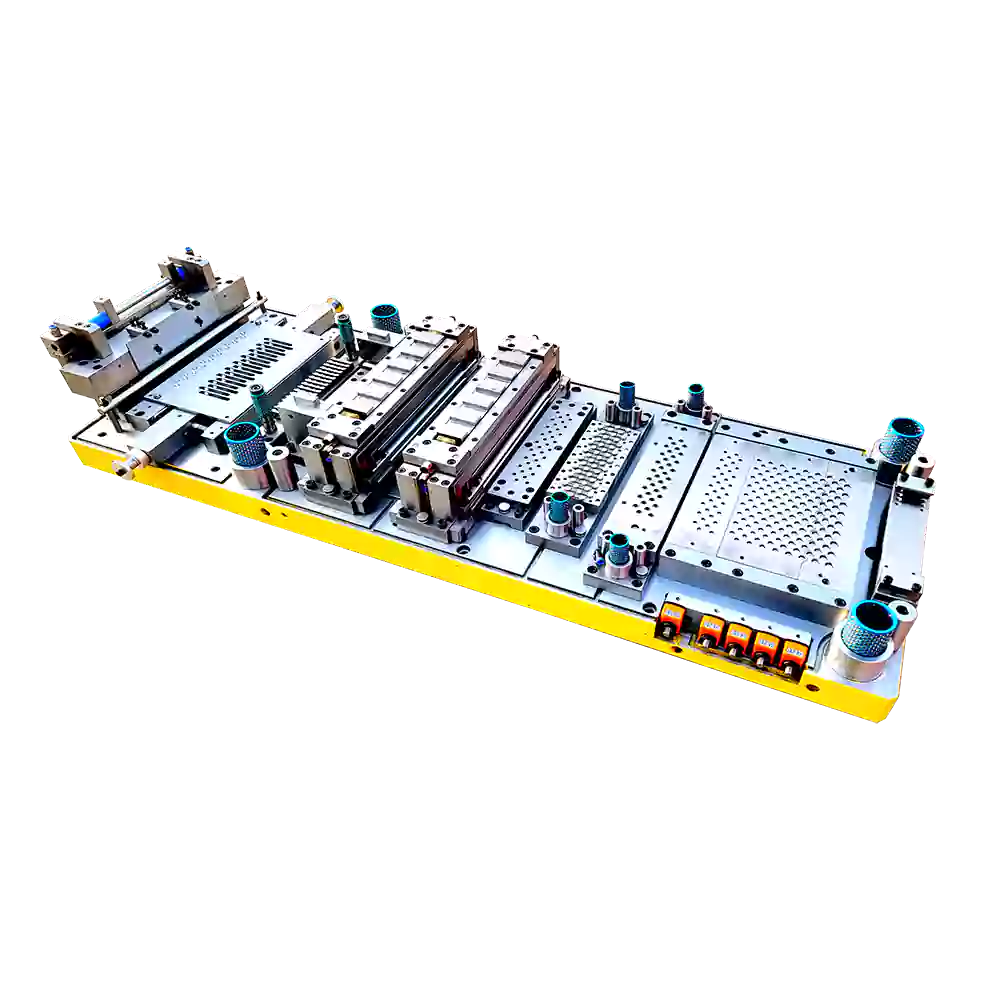

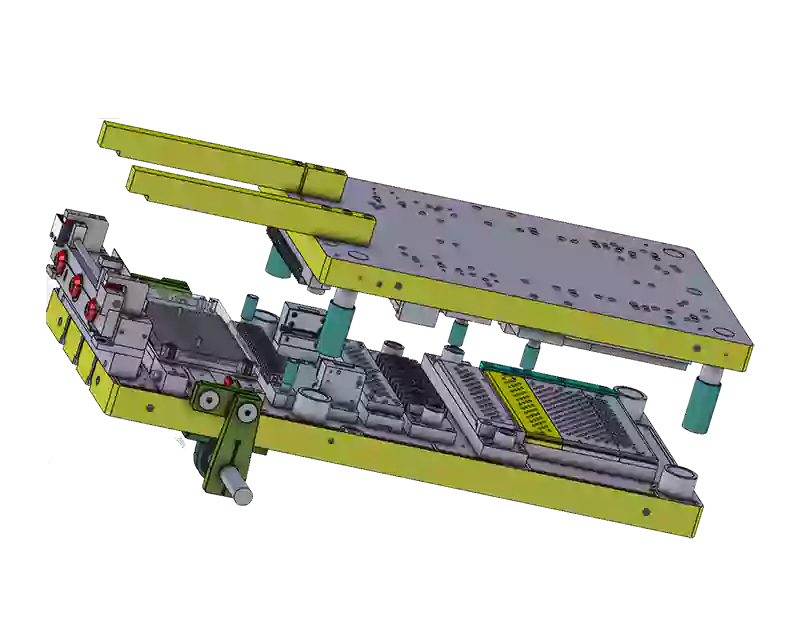

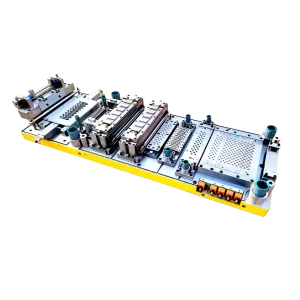

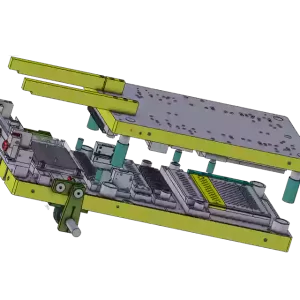

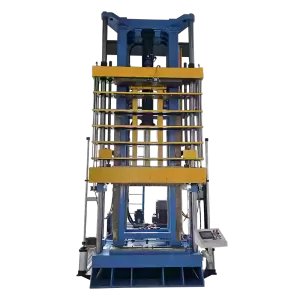

Why Choose SINOAK’s Fin Die

Content:

Unleash the power of SINOAK’s Fin Die – an essential tool for precision heat exchanger manufacturing. This cutting-edge die technology elevates your production capabilities and ensures the highest quality in heat exchanger fin production.

Benefits:

Precision Fin Tooling:

Achieve unparalleled precision in heat exchanger fin production with SINOAK’s Fin Die.

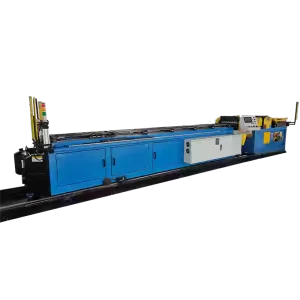

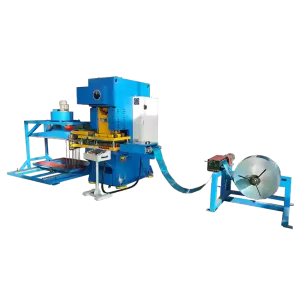

Efficient Manufacturing:

Optimize your production processes by integrating our efficient die technology.

Versatile Applications:

The Fin Die adapts to various heat exchanger configurations for diverse applications.

SINOAK Quality:

Rely on SINOAK’s reputation for delivering high-quality machinery, ensuring durability and reliability.

Why Choose SINOAK:

Innovative Technology:

SINOAK Machinery stays at the forefront of innovation, providing state-of-the-art solutions for heat exchanger manufacturing.

Efficiency Redefined:

Our Fin Die is engineered for efficiency, ensuring a seamless and streamlined fin production experience.

Customizable Solutions:

Adapt the die to your specific production needs, catering to a wide range of heat exchanger applications.

Application Scenario

By choosing SINOAK’s fin dies, you invest in precision, efficiency, and versatility for your heat exchanger manufacturing processes. Our high-quality fin dies ensure optimal performance in various applications, from air conditioning and refrigeration to automotive radiators and electronics cooling.

Internal and External Links

For more detailed information about our products and their applications, visit our main website. Check out our Semi-Automatic Hairpin Bender and Fully Automatic U-Bending Machine.

Explore additional resources on heat exchanger technologies at ASHRAE and industry news at ACHR News.

Contact Us for Fin Die Solutions

Stay connected with us on WhatsApp and WeChat: +86 15688803399

If you have any questions or need further assistance, feel free to contact us at [email protected].

View Related Videos:

نقد و بررسیها

هنوز بررسیای ثبت نشده است.